Zortrax M300 Dual 3D Printer MatterHackers

$ 5.090,00 $ 1.272,50

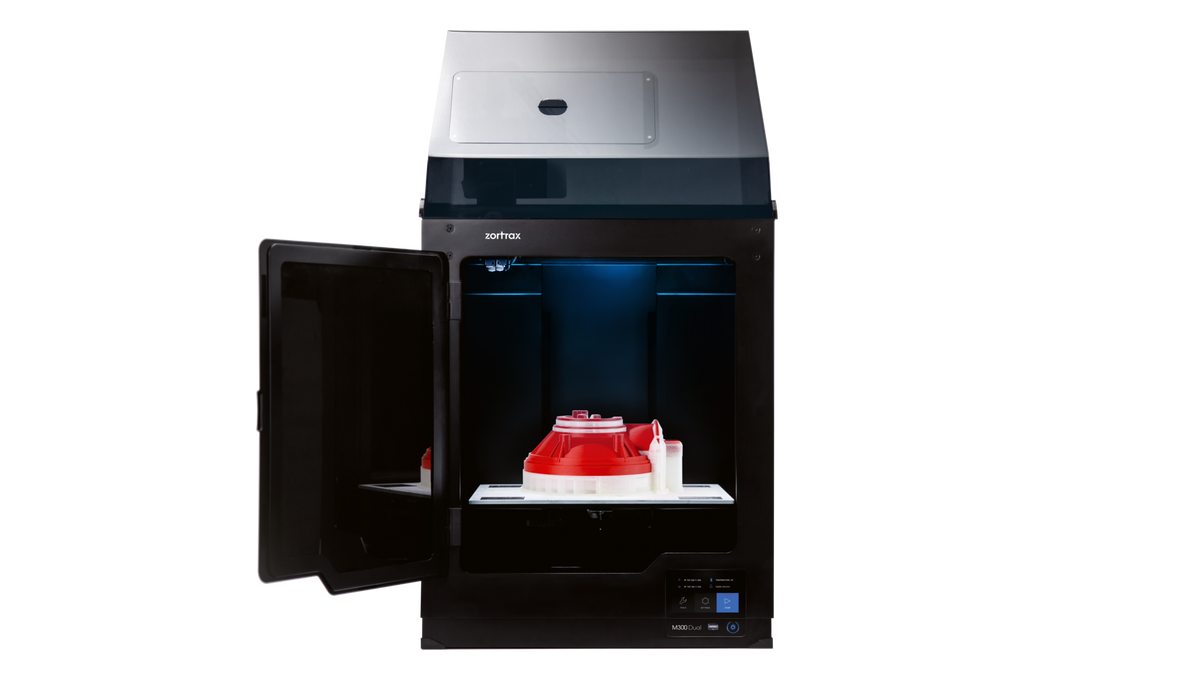

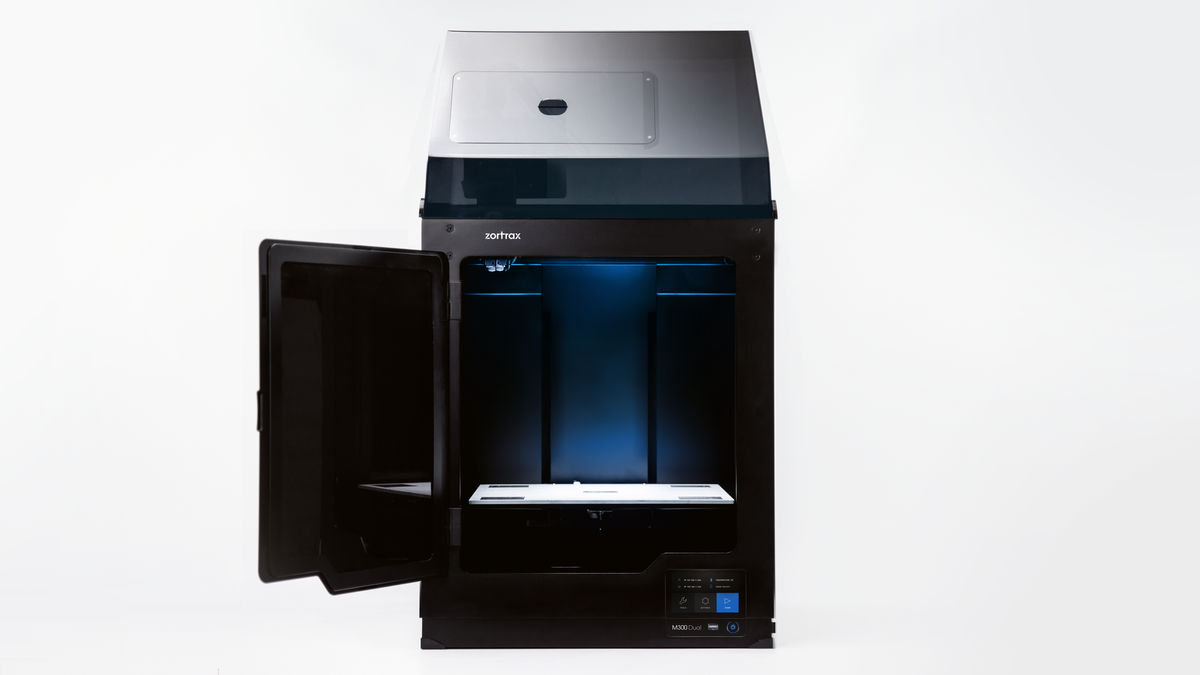

Zortrax M300 Dual

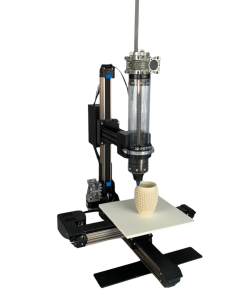

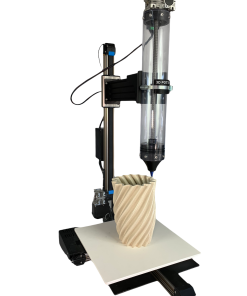

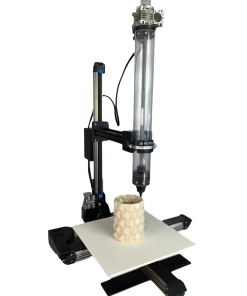

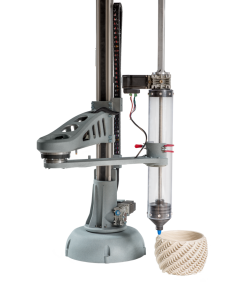

Professional Large Volume Dual Extrusion 3D Printer

Zortrax M300 Dual Parts

The LPD Plus technology designed for BIG industrial-grade results. |

|

|

|

|

For Tips & Tricks on how to print Xstrand GF30-PA6 1.75MM on the Zortrax M200 Plus, Zortrax M300 Plus and Zortrax M300 Dual

Industrial-quality results from desktop 3D printer |

|

|

|

Large workspaceIts large workspace measuring 265x265x300 mm is sufficient to print big models in one go. |

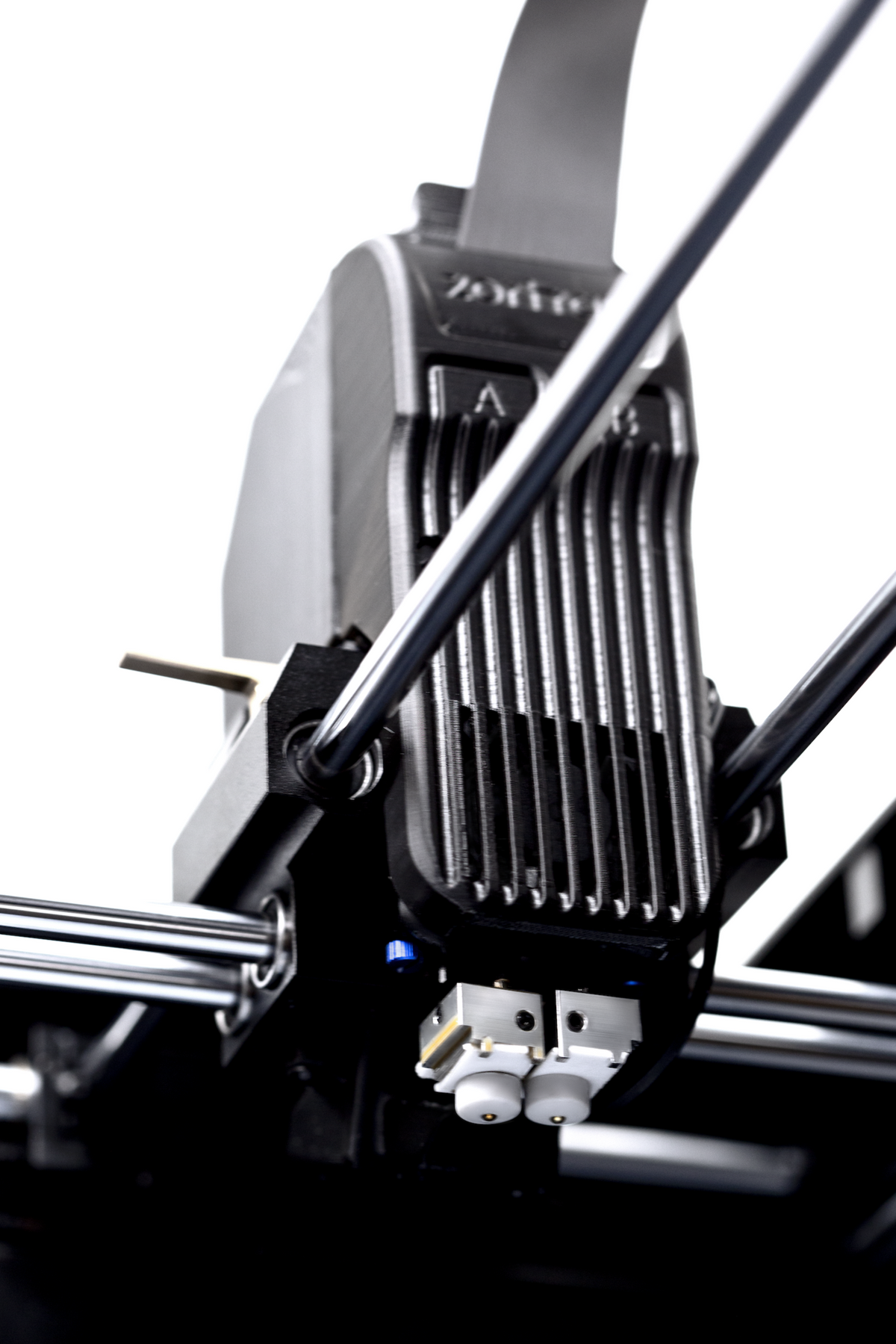

Dual-extrusion systemThe LPD Plus technology works with two nozzles and a double hot-end. |

Blackout response systemThe M300 Dual can detect a power outage and resume the printing from the same spot when the power is back on. |

|

|

|

Capacitive sensorThe CDS allows automatic calibration of the printer regardless of the type of build-platform installed. |

Advanced filament controlThe M300 Dual automatically pauses the print when the filament’s jammed, run out, or when the nozzle got clogged. |

External materials supportThird-party filaments available on spools are fully supported in both single and dual extrusion modes. |

Large format models made with a desktop-sized 3D printer |

|

|

|

|

|

Step 1 DesignYou can design models in all types of CAD software that support exporting files to .stl and .obj format or simply download them from the many online libraries. |

Step 2 PrintZ-SUITE can send an already pre-processed model to one or more of your printers over Wi-Fi or Ethernet network. |

Step 3 Remove supportsWater-soluble support filaments can be easily removed by rinsing. A dedicated Z-SUPPORT Premium dissolves quickly and leaves no remnants on the model. |

Step 4 Go forwardOnce the supports are removed, the model can work as a functional prototype or an end-use part in various industries. |

Scaling up to 3D printing farmsThe Zortrax M300 Dual’s wireless connectivity enables you to build a large cluster of remotely controlled 3D printers. Besides Wi-Fi, multiple M300 Dual 3D printers can also be networked through Ethernet or USB ports. |

Connect

|

|

|

|

Main features of Z-SUITE 2 for dual-extrusion technologyZ-SUITE is a dedicated slicing application that also works as a wireless command center of smart, reliable Zortrax 3D printers with Wi-Fi capability. It has a variety of functionalities enhancing the experience of using Zortrax M300 Dual. |

Raft-free 3D printing

|

|

|

|

Specification for Zortrax M300 Dual |

Device features |

|

Build volume |

265 x 265 x 300 mm (10.4 x 10.4 x 11.8 in) |

Nozzle diameter |

0.4 mm (0.016 in) |

Extruder |

Dual material extruder with material jam detection |

Extruder cooling system |

Two fans cooling the extruder; radial fan cooling the print |

Hotend |

Dual material hotend |

Platform |

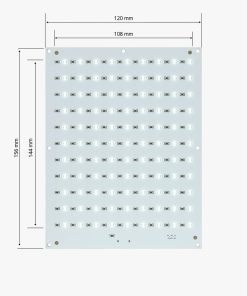

Heated; Perforated/Glass |

Material Endstop |

2 x Mechanical |

Connectivity |

Wi-Fi, Ethernet, USB |

Operation system |

Android |

Processor |

Quad Core |

Touchscreen |

4″ IPS 800×480 |

Camera |

Yes |

Electrical |

|

AC input |

110 V ~ 5,9 A 50/60 Hz ; 240 V ~ 2,5 A 50/60 Hz |

Maximum power consumption |

400 W |

Software |

|

Software bundle |

Z-SUITE |

Supported file types |

.stl, .obj, .dxf, .3mf |

Supported operating systems |

Mac OS X / Windows 7 and newer versions |

In the box |

3D Printer, Side Covers, Z-SUITE, Starter Kit, 1 spools of model material, 1 spool of support material, 2 spoolholders, Material Box, 1 perforated platform, 1 glass platform |

Printing |

|

Technology |

LPD Plus (Layer Plastic Deposition Plus) – advanced technology with the system of Dissolvable Support Structures |

Layer resolution |

100 – 300 microns (for 0.4 mm 0.016 in nozzle) |

Minimal wall thickness |

400 microns (for 0.4 mm 0.016 in nozzle) |

Platform leveling |

Automatic measurement of platform points height / manual measurement of platform points height |

Temperature |

|

Maximum printing temperature (extruder) |

310° C (590° F) |

Maximum platform temperature |

105° C (221° F) |

Ambient operation temperature |

20 – 30° C (68- 86° F) |

Storage temperature |

0 – 35° C (32- 95° F) |

Filaments |

|

Dedicated filaments |

Z-NYLON, Z-ABS, Z-ULTRAT, Z-PETG, Z-GLASS, Z-PLA, Z-ULTRAT PLUS, Z-SUPPORT PREMIUM |

External filaments |

Applicable |

Support |

Mechanically removed – printed with the same material as the model / Dissolvable – printed with a different material than the model |

Filament container |

Spool |

Filament diameter |

1.75 mm (0.069 in) |

|

|

|

|

|

|

|

|

|

|

|

|

|

SID: MLL8AVUX

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts