BCN3D Hotend X BCN3D

$ 199,95 $ 79,98

BCN3D Hotend X

Compatible with Epsilon W50 and Epsilon W27.

BCN3D Hotend X with a nozzle of 0.6mm is made from a special alloy of tool steel and opens up a whole new world of industrial applications. When paired with the BCN3D Epsilon, it allows you to print with fiber-filled materials, so you can print stiffer parts for the most demanding jobs. This hotend is immensely hard, but also maintains its hardness to high temperatures without softening.

The Hotend X is only compatible with Epsilon W50 and Epsilon W27. It is the right hotend to print with BCN3D fiber-filled materials PP GF30, PAHT CF15 and PET CF15.

The standard hotends use brass nozzles, these were designed to be used with soft filaments like PLA, ABS, PP, etc. But nowadays the 3d printing industry request other materials with new properties, that’s why the fiber materials have come to stay.

The downside? These materials are much more abrasive, they literally act like metal files when are extruded thought the nozzle. As you will see, it is not necessary to print many meters of these filaments to start causing irreparable damage to your brass hotends.

These pictures were taken after printing just 250gr of carbon fiber filled filament, using a brand new brass 0.4mm nozzle. You can compare the wear of the hotend X after printing 2.5 kg of various carbon filled materials, and glass filled materials too “right side hotend”. Ten times the amount of material (250g) that the brass nozzle on the left has printed.

The pictures are self-explanatory, the tip of the brass nozzle has worn down making the nozzle shorter in overall length, causing, for sure, calibration issues. The tip of the nozzle has also been rounded over into a dome shape due to abrasion.

E3D has carefully selected the steel to produce the hotend X and has included a combination of thermal and chemical treatments on the post-processing, creating an extremely hard and wear resistant nozzle.

To further increase the hardness and smoothness the nozzle X is plated with slick nickel. Then, the entire nozzle receives a ‘polyphobic’ nano-coating which prevents polymer adhering to the nozzle surface.

- Less build up, particularly of sticky and filled materials to the nozzle cone.

- Improved first layer reliability; the slick coating has a reduced tendency to ‘drag’ material, particularly at sharp corners where tracks can peel up.

- Slicker, smooth top solid layers with a glassy like finish as a result of the smooth laydown of material.

- Easier nozzle cleaning, what little material that does adhere is easily wiped away with a paper towel leaving a very clean nozzle.

It’s possible to get the same benefits using jewel tip nozzles, but this kind of nozzles restricts the flow due to an internal ‘step’ in the polymer flow path. This causes poor flow response, high back-pressure, and starvation of extrusion.

Hotend X tips are machined in one single piece providing a fantastic flow response and keeps exactly the same geometry and compatibility as the rest of the BCN3D hotends.

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Parts

3D Printer Parts

CNC Parts

3D Printer Parts

3D Printer Parts

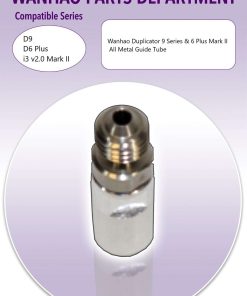

All Metal Guide Tube – Wanhao D9/D6Plus Mk2/i3Plus Mk2 Wanhao Precision Casting Co., Limited

3D Printer Parts

Aluminum Vat With FEP Pre Installed – Phrozen Transform Fast PHROZEN

CNC Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts