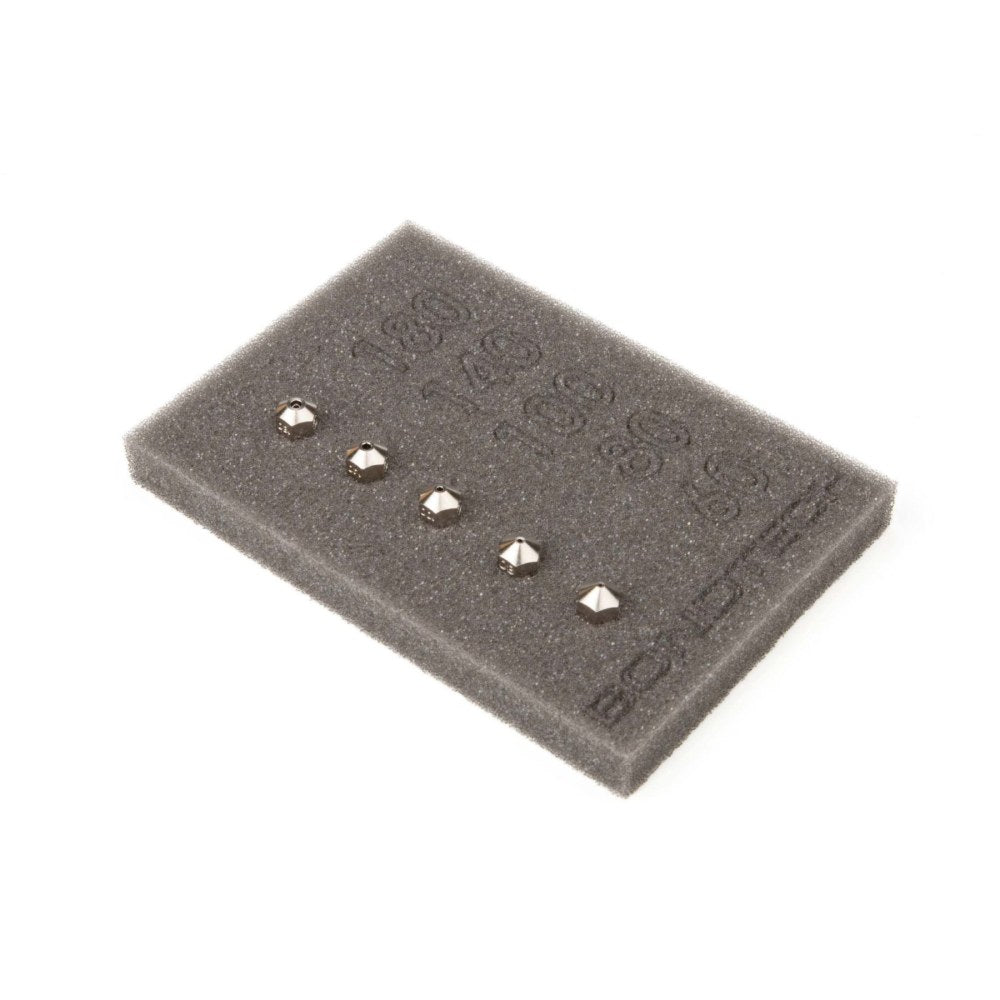

Bondtech CHT® Coated Brass Nozzle 5 pack Bondtech SE

$ 99,50 $ 49,75

Nozzles for High Flow Applications

Bondtech CHT® nozzles use patented core heating technology to increase melt capacity, allowing you to print more material faster. With Bondtech CHT® nozzles you can get at least 30% more flow with the same hotend. If you want to learn more about Bondtech CHT® high flow nozzles, keep reading or check out Bondtech’s whitepaper, Increasing Melt Capacity With 3 Nozzle Features.

Main Advantages of Bondtech CHT® Nozzles

- Higher melt capacity by increasing the surface area of the heating walls

- Affordable price

- Machined with ultra-precision

- Brass nozzle with Nickel coated surface

- Follows nozzle standards: RepRap (M6×1×7.5×12.5)

- May be used with 1.75 or 2.85mm hotends

Compatible With

- Mosquito® / Magnum

- Mosquito® Liquid

- Mosquito® Magnum+

- Copperhead™

- E3D V4, V5 and V6 blocks

- E3D Chimera and Kraken

- RepRap M6

Advantages of Bondtech CHT® Technology

Bondtech CHT® nozzles split the filament into 3 thinner strands allowing to melt the material from within. In doing so, the material melts faster and higher flow rates can be used.

Core Heating is a Patented Technology

Registration number: EP3445568A1

Nozzles for 3D printers made of metal with at least one or a multitude of holes to increase the surface area of the heating walls.

Advantages of the Nickel Coating

A Nickel coating is applied to Bondtech’s Coated Brass nozzles to provide protection against corrosion, erosion, and abrasion. Nickel coated nozzles have more corrosion resistance and lower coefficient of friction, which allows slicker feeding of material and delays plastic adhesion to the nozzle’s surface.

What’s Included

- 5 Bondtech CHT® Coated Brass Nozzles

- 1x 0.6mm nozzle

- 1x 0.8mm nozzle

- 1x 1.0mm nozzle

- 1x 1.4mm nozzle

- 1x 1.8mm nozzle

Recommended Materials

- PLA

- ABS

- HIPS

- PC

- TPU

- TPE

- Nylon

- PETG

- ASA

- PP

- PVA

Different Nozzle Sets for Different Materials

We recommend you to have several sets of nozzles because:

Using different materials with the same nozzles causes deposit build-up inside the nozzle. These deposits will cause blockages.

We recommend changing nozzles when changing materials.

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Parts

Aluminum Vat With FEP Pre Installed – Phrozen Transform Fast PHROZEN

CNC Parts

CNC Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

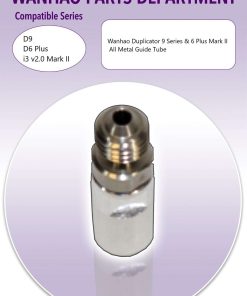

All Metal Guide Tube – Wanhao D9/D6Plus Mk2/i3Plus Mk2 Wanhao Precision Casting Co., Limited