Epsilon W50 BCN3D

$ 8.495,00 $ 2.123,75

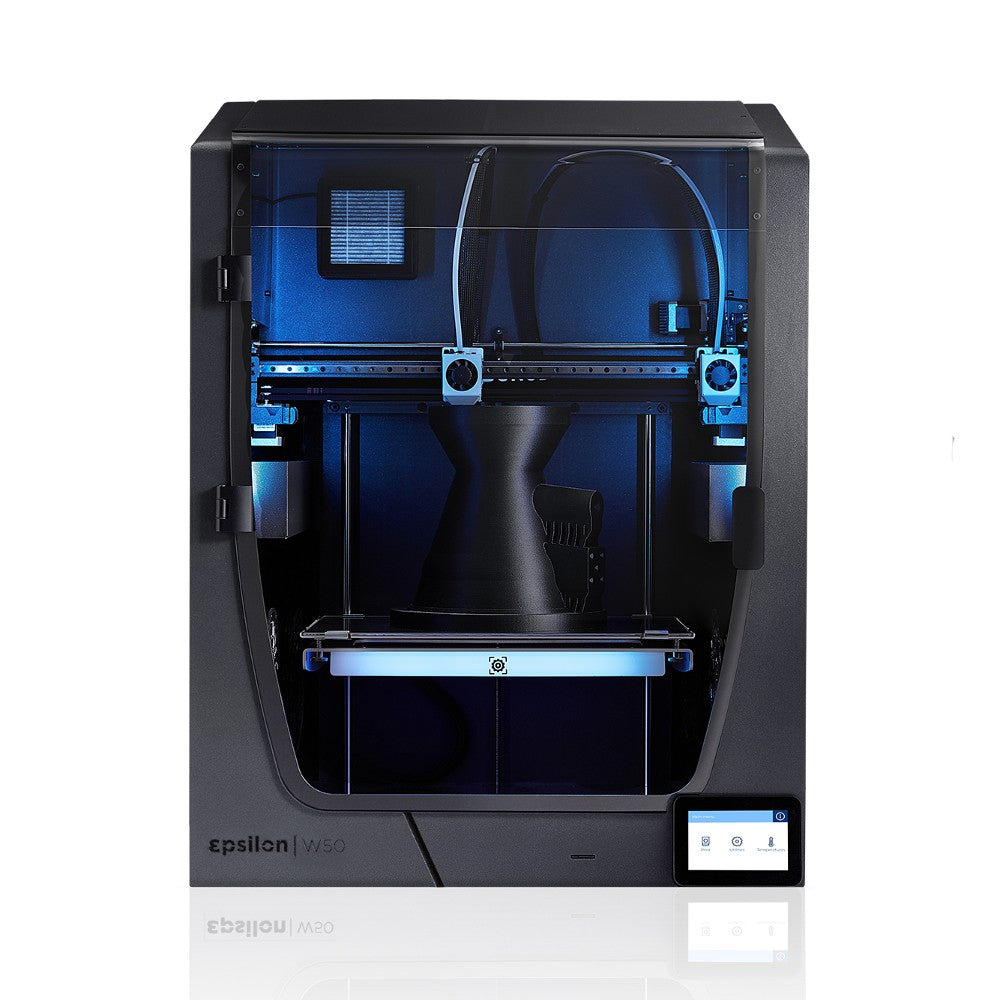

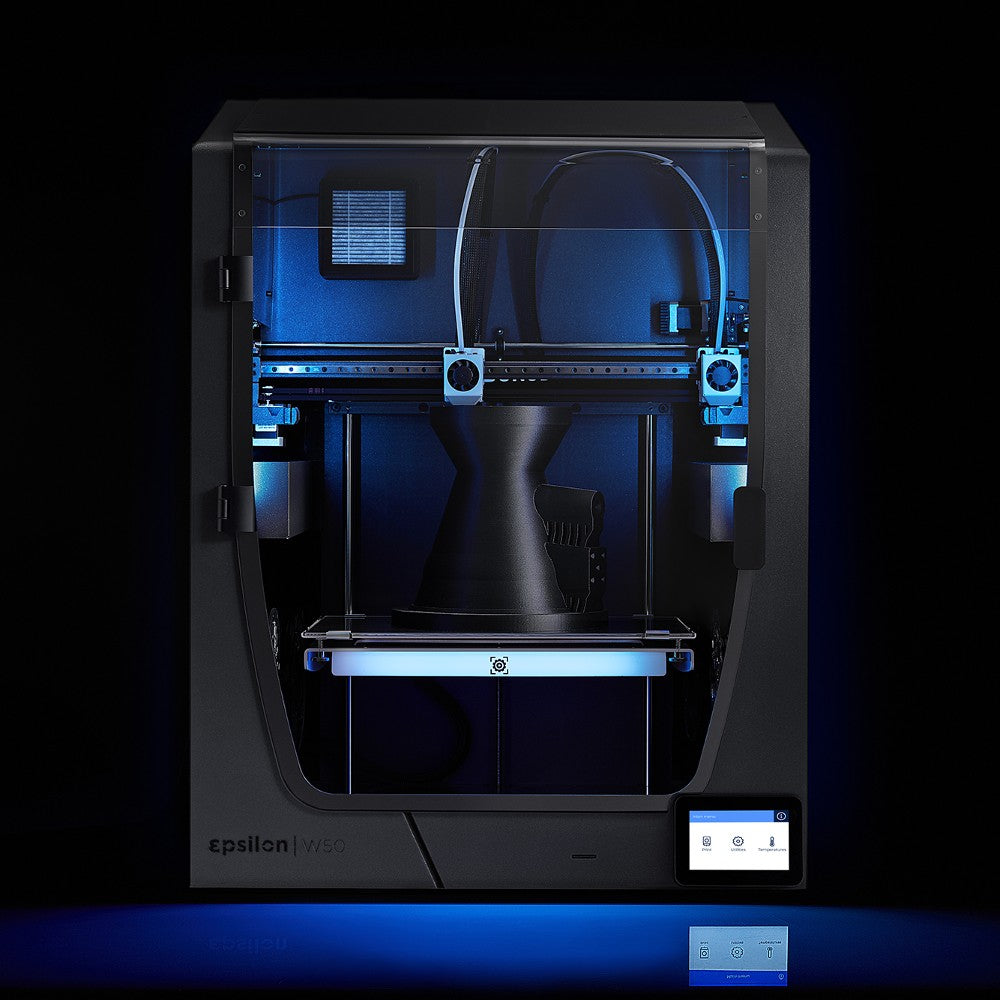

BCN3D Epsilon W50

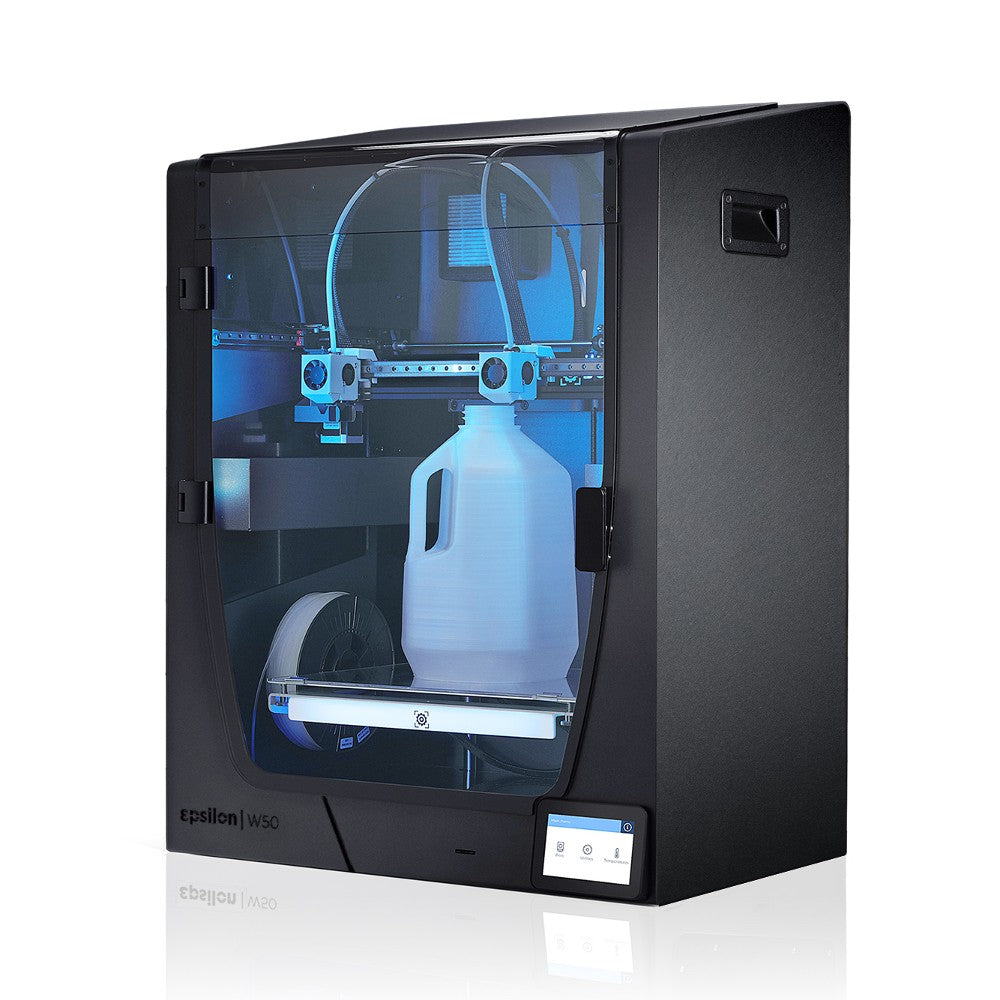

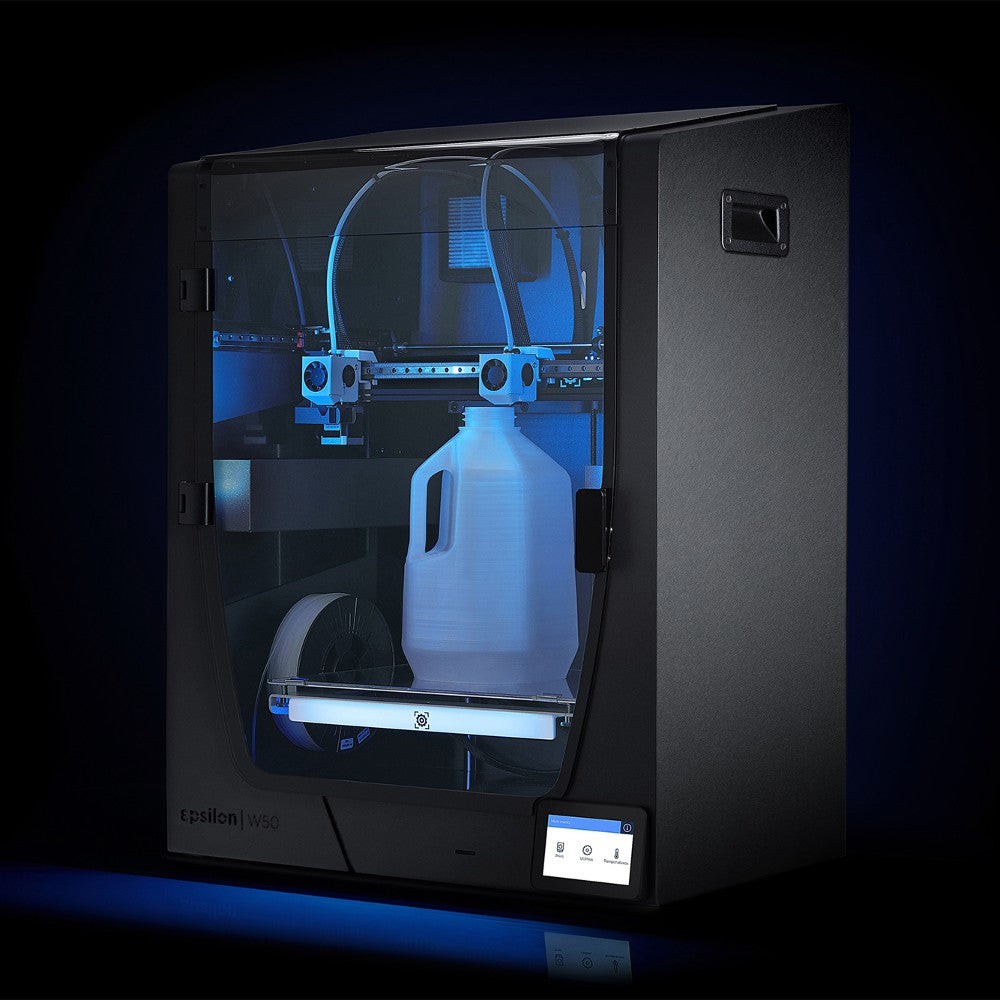

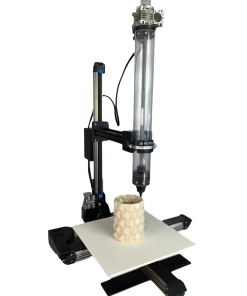

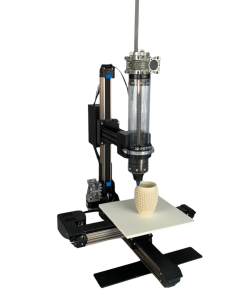

The Epsilon W50 is a powerful professional 3D printer, designed to deliver large-scale parts with industrial-grade materials, thanks to features such as its passive heated chamber and full enclosure. Powered by Independent Dual Extruder (IDEX) system, the Epsilon W50 delivers exceptionally strong functional parts with quality and precision.

Already trusted by 15,000+ engineers and designers

Massive print volume

Epsilon W50

Volume: 50 Liters

420mm

Length

300mm

Width

400mm

Height

Developed by BCN3D, the disruptive Independent Dual Extrusion System technology makes the difference in 3D printing.

Duplication Mode

A setting that prints identical models simultaneously, doubling the production capacity

Developed by BCN3D, the disruptive Independent Dual Extrusion System technology makes the difference in 3D printing.

Mirror Mode

A mode that enables printing mirrored designs symmetrically and speeds up iteration.

Developed by BCN3D, the disruptive Independent Dual Extrusion System technology makes the difference in 3D printing.

Soluble Supports Mode

A process that prints soluble parts to create intricate structures and avoid geometric limitations.

Developed by BCN3D, the disruptive Independent Dual Extrusion System technology makes the difference in 3D printing.

Multimaterial Mode

A technique that makes it possible to print two different materials and combine their properties.

Designed to perform. Full enclosure & passively heated chamber.

The Epsilon W50 and the Epsilon W27 count on a fully enclosed chamber keeping internal temperature controlled, where it can reach up to 60°C, and a heated bed reaching up to 120°C.

Safety Features

HEPA filter

The BCN3D Epsilon printers are equipped with a HEPA filter, which protects your working environment from potentially harmful particles when printing with industrial materials.

Safety pause

The Safety Pause feature will stop the printing process every time the enclosure door is opened, so that your experience will be fully safe through and through.

Carbon filter

The carbon filter on the BCN3D Epsilon printers shields your environment from any potentially harmful fumes produced by the materials used.

Key Features

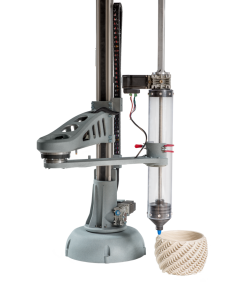

Bondtech™ Extruders

This extruder features high-tech dual drive gears by Bondtech™, offering more control, sharper details, and superior performance for any type of filament.

Filament Runout Sensor

A job-saving sensor that detects when the filament is finished and pauses the printing process until it is reloaded again.

Hotends

The hotends have been carefully designed to deliver the smoothest and most reliable extrusion.

Autocalibration

The autocalibration system incorporated in the BCN3D Epsilon calibrates the entire printer in less than 6 minutes by measuring multiple points to automatically adjust the printing surface height and (XY) offset between both nozzles. Always obtain a perfect first layer, without any user intervention needed.

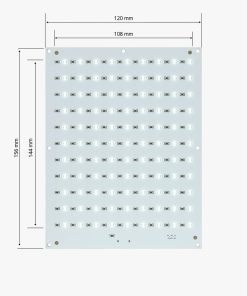

Heated bed up to 120ºC

The BCN3D Epsilon Series is equipped with a heated bed that can reach up to 120ºC, ideal to print with engineering-grade materials and avoid warping issues.

Aluminium Frame

Sturdy aluminum frame for guaranteed strength and durability on your workfloor.

Multilingual 5″ touchscreen

The BCN3D Epsilon Series is equipped with a multilingual intuitive interface that guides you through its advanced features. Supported languages: German, English, Spanish, French, Italian, Japanese, Portuguese, Chinese.

Create big functional parts with solid mechanical properties.

Unlock a wide range of technical applications with the industrial-grade BCN3D Filaments, developed by the renowned chemical companies: BASF and Mitsubishi Chemical, or work confidently with any third-party material of your choice thanks to BCN3D’s Open Filament System.

BVOH, Tough PLA, PLA, PET-G, TPU 98A, PVA, ABS, PA, PP

BCN3D Advanced Material Bundles

BCN3D Metal Pack

By bundling the Epsilon with the BCN3D Metal Pack, you’ll be able to print not only thermoplastics, but also metal-filled filaments. The parts produced by this process have practically identical behavior to those produced by MIM or CNC and offer an office-friendly solution with far more design freedom. The pack includes both 316L and 17-4 PH accompanied by an exclusive hotend for metal and consumables. After printing, debinding and sintering processes can be carried out externally through the current Forward AM authorized network of service suppliers.

BCN3D Fiber Pack

By bundling the Epsilon with the BCN3D Fiber Pack, you’ll be able to print not only thermoplastics, but also fiber-filled filaments and achieve elite mechanical properties. This pack has all you could ever need for printing with fiber-filled materials, with a trio of materials accompanied by specially designed hotends and consumables. We strongly recommend using this pack together with the Smart Cabinet (SC) on your Epsilon to keep the filaments in optimal humidity conditions.

Enhance with Compatible Smart Cabinet

SMART CABINET

The Smart Cabinet completes the Epsilon ecosystem, offering seamless integration with your BCN3D Epsilon printers and boosting their performance. Its filament humidity control keeps your materials in optimal condition, and its uninterruptible power supply protects your work at all times, avoiding the risk of losing your print job due to power outages.

Smart Cabinet Key Features

Humidiy-controlled environment

Designed to extend the service life of your materials, the alumina absorbs the moisture from the air in the chamber. Once it becomes saturated, this material is isolated from the filaments and gets heated up until it releases the moisture, purging it out of the system. This process effectively keeps the filament dry and in optimal condition for its use.

Print while in storage

The dehumidifier can fit up to 10 small spools (weight between 750 g – 1 kg and width up to 55mm) or 4 big spools (weight up to 2,5kg). These can be loaded to your 3D printer directly from this humidity-controlled environment, therefore allowing it to print while keeping the materials in perfect condition.

Complete working station

The tool drawer provides you with every utensil you might need, and thanks to the extra space for your laptop or tablet you count on a full working station right by your 3D printer.

Uninterruptible Power Supply (UPS)

The UPS electric signal filtering protects your print from any possible outages and micro-cuts on the electric current. In the event of a blackout of up to 10 minutes, this technology will enable the 3D printer to automatically resume the printing process once the power is back. In case of a longer outage, the UPS will save the printer’s last position, so that you can manually resume the printing process at any time and without consequences for your print.

Storage and transportation

Maintain your workspace organized and clean at all times thanks to the ample storage space, designed to keep extra building plates and unopened filament spools – and thanks to the Smart Cabinet’s transportable structure, your printer can be easily moved across your facilities.

A Unique Ecosystem

BCN3D Cloud

The BCN3D Epsilon 3D printers are equipped with the latest connectivity features. Easily send your print files when connected to the network for a hassle-free workflow with the BCN3D Cloud platform. And forget about manual firmware upgrades thanks to Over The Air (OTA) updates, who will ensure that your printer is always up to date (activated on demand).

BCN3D Stratos

BCN3D Stratos is a straightforward slicing software, designed for speed and efficiency while still ensuring top-quality prints for a powerful 3D printing process. The user-friendly interface is free and compatible with all BCN3D Sigma and Epsilon printers.

BCN3D Filaments

Industrial-grade materials manufactured by BASF and Mitsubishi Chemical and designed to deliver outstanding results for BCN3D printers.

BCN3D Hotend family

A wide range of nozzle sizes which enables printing anything from small, very precise details to massive, solid parts in less time.

Specifications for BCN3D Epsilon W50

| Printer Properties | |

|---|---|

| 3D Printing Technology | Fused Filament Fabrication (FFF) |

| Architecture | Independent Dual Extruder (IDEX) |

| Filament Management System | Not included |

| Printing Volume | 420mm x 300mm x 400mm (16.5” x 11.8” x 15.8″) |

| Build Chamber | Passive Heated Chamber Fully enclosed Safety Pause |

| Air Filtering | Category H13 HEPA filter Active Carbon filter |

| Number of extruders | 2 |

| Warranty | 1 year |

| Extruder System | Extruder Bondtech™ high-tech dual drive gears Hotends optimized and manufactured by E3D |

| Printing modes | Single mode Duplication mode Mirror mode Multimaterial mode Soluble Supports Mode |

| Calibration system | Based on a piezoelectric sensor Main Features: * Accurate Z homing * Quick assisted bed leveling * Automatic XYZ offset extruder calibration * Automatic Mesh Mapping |

| Electronics | Single Board Computer: Toradex ARM Compute Module Motion Board: BCN3D Electronics with Independent Stepper Drivers |

| Firmware | Firmware BCN3D Embedded Linux distribution BCN3D Epsilon – Marlin |

| Heated Bed | Silicone thermal pad |

| Screen | 5″ full color capacitive touchscreen |

| Supported languages | Spanish English German French Italian Japanese Portuguese Chinese |

| Supported files | *.gcode |

| Operating sound | 49 dB(A) |

| Nozzle diameter | Brass nozzle: 0.4mm (default) | 0.6mm | 0.8mm | 1.0mm Hotend X: 0.6mm – Hotend M: 0.4mm |

| Certifications | CE / FCC |

| Connectivity | Offline printing: SD card Online printing: WiFi or Ethernet (through BCN3D Cloud) |

| Materials | |

|---|---|

| Filament | 2.85 ± 0.05 mm |

| Compatible materials | Standard Materials: PLA, Tough PLA, PET-G, TPU 98A, PVA, BVOH Technical materials: ABS, PP, PA Composite materials (only with Hotend X): PP GF30, PAHT CF15, PET CF15 Metal Materials (only with Hotend M): Ultrafuse 316L, Ultrafuse 17-4 PH |

| Open filament system | Yes |

| Physical Properties | |

|---|---|

| Overall Dimensions | 690mm (W) x 530mm (D) x 900mm (H) (27.2” x 20.9” x 35.4”) |

| Weight | 37kg (81.6 lb) |

| Shipping box dimensions | 800mm (W) x 600mm (D) x 1370mm (H) (31.5” x 23.6” x 53.9”) |

| Shipping weight | 62kg (136.7 lb) |

| Shipping method | US Pallet |

| Printing Properties | |

|---|---|

| Recommended profiles | Layer height: 0.2mm | 0.3mm | 0.4mm (depending on nozzle diameter) |

| Layer height | 0.05mm – 0.5mm (custom profiles) |

| Positioning resolution (X / Y / Z) | 1.25µm / 1.25µm / 1µm |

| Operating temperature | 15 ºC – 30 ºC |

| Extruder maximum temperature | 300 ºC |

| Heated bed maximum temperature | 120 ºC |

| Build chamber maximum temperature | 60 ºC (depending on operating temperature) |

| Electric Properties | |

|---|---|

| Input | AC 100-240V, AC 8.4-3.5A, 50-60Hz |

| Maximum power consumption | 840W |

| Software | |

|---|---|

| File preparation software | BCN3D Stratos |

| Operating Systems | Windows, Mac, Linux |

| Supported files | STL, 3MF, OBJ, AMF, DAE, ZAE, CTM, PLY, X3D, GLB, GLTF |

| Wireless connectivity | BCN3D Cloud |

| Supported browsers | Google Chrome, Mozilla Firefox, Microsoft Edge, Safari, Opera |

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Parts

3D Printer Parts

Bambu Lab Heatbed Surface Magnet (with Cutout) – P1 Series Bambu Lab

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts