Fusion3 EDGE 3D Printer Fusion3 Design, LLC

$ 8.849,00 $ 2.212,25

Fusion3 EDGE

Combining Fusion3’s Unrivaled Print Quality with High Speeds, Ease of Use, and Reliability! USA Made!

Free Shipping to most continental US locations

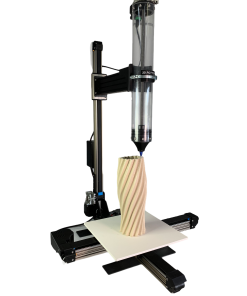

Fusion3’s all new EDGE 3D Printer gives you everything you need for an industrial manufacturing 3D printer. Building on the success of their Fusion3 F410 3D Printer, the Fusion3 EDGE is larger, faster, and more precise than it’s predecessors and competitors. Clocking in at up to 200mm/s, the EDGE gives you the option of super high throughput with a tolerance of ±.003″ per inch. Whether you use 3D printing for rapid prototyping, scale models, or even end-use parts, the Fusion3 EDGE is the perfect machine to meet your use-case. If you are not convinced yet, keep reading to learn more about the capabilities of the Fusion3 EDGE 3D Printer, or reach out to us at sales@u3dps.

Exceptional 3D Print Quality at High Speeds

Fusion3’s ‘F-Series’ motion control system delivers faster speeds and greater visual quality and tight tolerances.

Validated through millions of operating hours with thousands of customers, EDGE utilizes Fusion3’s “F-Series” platform; utilizing upgraded motion control components including all-new linear rails, Gates 2GT2 belts, and specially tuned stepper motors. With these improvements Fusion3’s EDGE 3D printer has attained even faster speeds and tremendous improvements in print quality using standard print settings. These improvements have also enabled unique features such as a new “Fast” 3d printer mode used for printing certain materials at 200mm/sec using a .4mm print head.

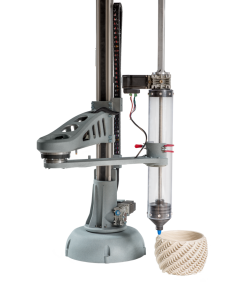

New Anvil 3D Print Head System

Patent-Pending technology provides greater reliability, performance and easier to maintain.

Fusion3’s patent-pending ANVIL print head system combines precision milled print head components with a surgical steel print tube used in place of the traditional screw-in 3D printer nozzle. The ANVIL print head components are precision milled, and utilize a high-quality, high-temperature heater cartridge and a PT-1000 temperature sensor. Use of the single surgical steel print tube enables faster 3D printing and is wear-resistant for use with abrasive filaments such as carbon fiber or fiberglass-reinforced filament. In addition, the single tube design is more reliable, eliminating the chance of leakage found in a traditional screw-in nozzle print head, and inexpensive and easy to replace, translating to lower operating cost.

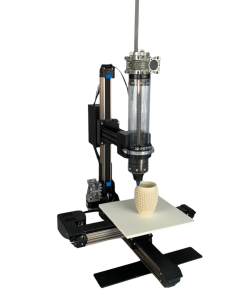

Largest Fusion3 3D Printer Ever

Faster print speeds, more heat translate to better large engineering-grade parts in less time.

Easy to Operate & Maintain

New features to assist users with operation and maintenance, without sacrificing performance & flexibility.

Durable & Reliable 3D Printing

Our customers require maximum uptime. Fusion3 engineers and supports our 3D printers to achieve this goal.

EDGE features a new, upgraded V3 extruder that uses a belt drive system and an upgraded filament detection monitor that can be tuned to different detection settings based on the material printed. At customer’s requests, Fusion3 included new ‘push to fit’ connectors for the bowden tube to make serving easier. Combined with the new linear rail system and bed leveling, EDGE is an increasingly robust and durable system for use in the most demanding environments.

However, should customers require assistance with their 3D printers, or in the unlikely event of an issue, Fusion3 provides the best warranty in the 3D printing. In addition to the best warranty in 3D printing, Fusion3 also provides free technical support for the life of your Fusion3 3D printer.

Widest Variety of 3D Printer Materials

Fusion3’s testing & certification process ensures our customers can successfully print the widest variety of materials for 3D printing ‘out of the box’.

Fusion3’s rigorous material testing and certification process ensure that customers can print the widest range of materials purchased from a variety of quality suppliers. Using the ¼” aluminum tool plate print bed with glass print surface (standard), our customers can print materials from all major categories including (but not limited to): PLA, ABS, ASA, Reinforced Materials including Carbon Fiber, Kevlar and Fiberglass, Flexible, Nylons, PET/PETG and Polycarbonate.

With the addition of an optional magnetic tool plate and various optional magnetic print surfaces, customers can now print new materials, including Polypropylene, PVDF, and 316L Stainless Steel.

Safe & Comfortable for your Work Environment

Every new 3D printer model we look to incorporate additional features to drive further comfort, safety and convenience.

Focus on Security

Options for customers who safeguard proprietary & sensitive information within their 3D printing workflow.

Many of Fusion3’s customers wish to safeguard their proprietary and sensitive information within the 3D printing workflow. The company offers two versions of EDGE to meet the different security needs of our customers.

The Standard Version of EDGE has open USB ports, wired and wireless networking, and convenience features to actively communicate status beyond the device.

Fusion3 designed the Secure Version of EDGE for companies, government, military, and similar organizations with strict information security guidelines. This version ships with only Ethernet networking, a locked USB port, no features that communicate beyond the device.

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts