Get a Grip Workholding Kit Carbide 3D

$ 48,00 $ 28,80

Get a Grip Workholding Kit

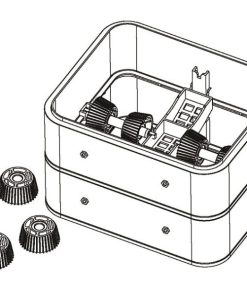

We’re proud of our Tiger Claw Clamps and our Lock Stops, but there is one problem, they’re not cheap. They’re both machined from solid aluminum or stainless steel so there’s no way around the cost. Based on the popularity of our Essential Clamps, we decided to make a full injection-molded workholding setup.

Presenting the Get A Grip Workholding Kit, a full workholding kit with everything you need, even for advanced machining setups.

What’s included?

- Essential Clamps (Qty 4)

- Essential Claws (Qty 4)

- Essential Stops (Qty 4)

- Essential Corner Square Set

- Spacers/shims (Qty 4)

- Teez-Nutz (Qty 12)

- M6 x 16 Socket head screws (Qty 20)

- M6 x 30 Socket head screws (Qty 4)

- M6 x 40 Socket head screws (Qty 4)

Compatibility

The Get A Grip Workholding Kit is compatible with all Shapeoko 4, Pro, and HDM machines using the included Teez-Nutz. If you have a Shapeoko 3 or earlier, the clamps and corner square will work fine, but you’ll need to provide T-nuts or other anchors for your table.

Note that the Essential Stops and the Essential Corner Square have a standoff molded into the base to put them slightly above the height of the MDF on a stock Hybrid Table. If you’ve taken a skim cut on your Hybrid Table then they may rest a little further above the MDF. This gap is OK. The standoffs allow the corner and stops to rest on the aluminum t-track for maximum rigidity.

The Essential Claws include a separate spacer so they can be used on the Hybrid Table or attached to flat fixture plates.

Are these strong enough?

Everything in this kit (other than the Teez-Nutz and the hardware) is injection molded from glass-filled nylon, a very strong and very tough material. Because they’re injection molded, the plastic is strong and uniform all the way through, unlike 3D printed clamps that tend to fail along build layers.

Essential Corner Square Kit

The injection-molded corner square set included here will do a great job at helping you set a repeatable stock location but it’s not as perfectly square as the aluminum Corner Square Guide. This is due to the small distortions that occurs as injection-molded parts cool. With proper technique, it will be accurate enough for most applications.

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

CNC Accessories

3D Printer Accessories

.4MM drill cleaning tool for 3D nozzle cleaning Wanhao Precision Casting Co., Limited

CNC Parts

3D Printer Accessories

3D Printer Accessories

CNC Machine

CNC Parts

CNC Accessories

3D Printer Accessories

CNC Parts

3D Printer Parts

3D Printer Accessories

3D Printer Parts

3D Printer Accessories

3D Printer Accessories

3D Printer Parts

CNC Machine

CNC Accessories

CNC Machine

CNC Accessories

CNC Accessories