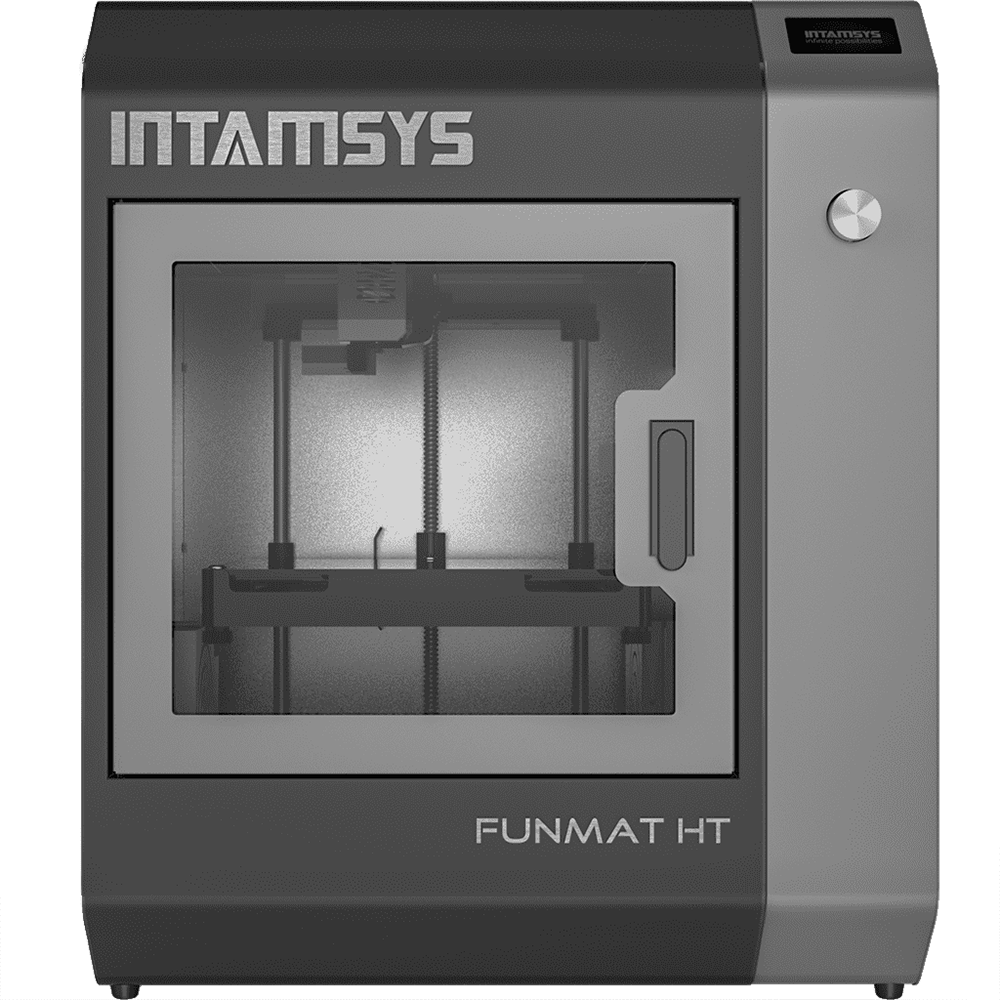

Intamsys Funmat HT 3D Printer Intamsys

$ 5.995,00 $ 1.498,75

Intamsys Funmat HT

Affordable High Temperature 3D Printing

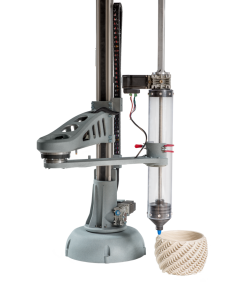

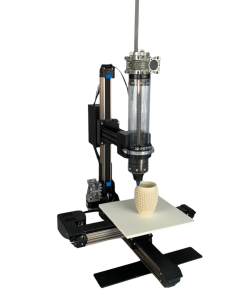

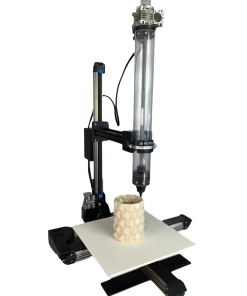

The Intamsys Funmat HT was designed to be an affordable and accessible entry into the world of high performance, advanced material 3D printing. The Funmat HT can print high temperature materials like PEEK, PEKK, Ultem, and more. These high performance 3D printing filaments have incredible chemical and mechanical properties.

3D printing with high performance materials can revolutionize your workflows through rapid iterative design, functional prototypes, and even end-use parts that can’t be made using traditional manufacturing technologies. The Intamsys Funmat HT’s advanced thermal design makes printing with even the most demanding materials easy. The Funmat HT offers a 90°C actively heated build chamber, a 160°C heated build plate, and a 450°C high temperature extruder with an all-metal hotend.

Smart Design for Continuous Production

High-Speed High-Precision

Actively Heated Chamber

Sensor Assisted Automatic Leveling

Multitude of Functional Materials

High Safety Standard

Key Features & Benefits

Smarter Design

Automatic leveling, filament jam warning, power failure recovery

Industrial Grade Configuration

Industrial grade components for high-precision and high-quality 3D printing

Advanced Thermal Design

Heated chamber and filament box, liquid hotend cooling system, 500°C (932°F) max hotend temperature

Best-in-Class Safety

Equipped with best-in-class safety components. CE (EMC/RED/LVT) certified for industry grade application standard

Industrial 3D Printing on your Desktop

The Intamsys Funmat HT is a 3D printer capable of printing industrial grade materials on top of your desk. Most industrial 3D printers have a massive footprint, requiring a permanent dedicated space in a workshop or on the manufacturing floor. The Funmat HT can save you valuable space in an already cramped work area while giving you many of the same capabilities.

Not only does the Intamsys Funmat HT save you valuable space, it also saves you a lot of money. Many 3D printers capable of printing high temp materials can cost hundreds of thousands of dollars. The Funmat HT makes 3D printing for your business affordable and accessible. Giving you a quick return on investment, allowing you to continue to grow.

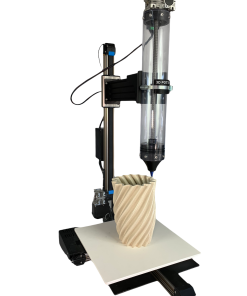

High Precision Customization & Production

Additive Manufacturing and 3D printing is an incredible tool to create custom-made parts at much lower costs than traditional manufacturing methods. You no longer need manufacturing runs in the thousands. With 3D printing you can have production runs of only a single part with low to no added fixed costs. The Intamsys Funmat HT can enable this low volume custom production with incredibly strong thermoplastics with high precision.

Open Material System with Infinite Possibilities

Intamsys is committed to providing the best 3D printing experience to customers. So they developed their own engineering grade filament solutions designed specifically for printing with the Intamsys Funmat line of 3D printers.

In order to truly fulfill their mission of providing the best 3D printing experience possible, the Funmat HT has an open-source filament system. This means you can use any 1.75mm filament available on the market. Now you can experiment with cutting edge materials, or limit costs by shopping around.

Applications & Use Cases

- Automotive

- Medical

- General Manufacturing

Automotive

Rapid Design Iteration | Spare Parts | Swift Production

Rapid Design Iteration

Engineers can leverage 3D printing technology to quickly create multiple iterations of functional prototypes. These prototypes can be tested for various structural, functional, and material properties. Based on these results, modifications can be made and produced within the same day. 3D printing can significantly reduce time-to-market by streamlining the product design process.

Availability of Spare Parts

Inventory costs of spare parts is a major cost component for automotive manufacturers. Combined with the shortened life cycle of automotive parts, spare part inventories can be hard to manage.

Using 3D printing, auto part manufacturers can shift to virtual inventory. Inventory costs can be cut by maintaining a digital repository of spare part models. Allowing manufacturers to produce parts on demand rather than stock thousands of physical parts. This also allows manufacturers to provide parts and supports for outdated models.

Production Lead Time

3D printing can expedite production lead times and time-to-market by producing parts required in limited, niche quantities. A prime example of this is custom tooling for specific models. Producing small quantities of highly custom parts can be very expensive and take a lot of time. 3D printing can hasten this process exponentially by allowing companies to manufacture these parts in house in the exact quantities necessary.

3D printing can also limit production downtime by speeding up the production of replacement parts and tooling. If a part breaks, a replacement can be manufactured in house the very same day. Traditionally, replacement parts need to be ordered from a 3rd party and could be received weeks later.

Medical

Pre-Surgical Models | Surgical Guides | Custom Implants & Prosthetics

Pre-Surgical Models

The creation of pre-surgical models is one of the major applications of 3D printing by medical researchers and practitioners. 3D printing shines as an informative tool by giving the medical practitioner the ability to print models that exactly match their patient.

Using CT scans, 3D models of an individual’s anatomy can be created. These models can then be printed with a 3D printer. This allows medical professionals to see exactly what is going on inside a patient and more accurately diagnose patients and prepare for surgeries.

Surgical Guides

Surgical guides are another great use for 3D printing in the medical field. Surgical guides are frequently used for the insertion of implants into the human body. They often require a high level of customization to fit each patient’s specific needs.

Intamsys 3D printers can print with chemical stable and safe materials. Perfectly customized surgical guides can quickly and at a lower cost than traditional methods.

Surgical Implants

Surgical implants often require high levels of customization to fit a patient’s body. These custom implants allow patients to enjoy life to the fullest, and are a critical treatment tool. Titanium and PEEK are typically used to create these implants because they are bio-compatible.

Printing surgical implants out of PEEK is easy on an Intamsys 3D printer. Implants 3D printed with PEEK can be created substantially more quickly than titanium. The implants are also much less expensive.

General Manufacturing

Jigs & Fixtures | Rapid Prototyping | Low-Volume Production | Virtual Inventory

Rapid Prototyping & Injection Mold Verification

3D printing can help any company during the design phase, even businesses who utilize mass production. 3D printers enable business to design, produce, and test functional prototypes very quickly. This helps reduce time-to-market of new products and create more well tested products.

3D printing can also help verify injection molding dies. Injection molding dies can be very expensive. Even a single mistake can force companies to order new dies. 3D printing allows companies to print and test both the object and the die itself before ordering. Saving the company potentially thousands of dollars.

Low Volume Production

Due to fixed costs of production, manufacturing low volumes of parts through traditional manufacturing methods can be very expensive and time consuming. 3D printing is the perfect solution to low volume production. Intamsys 3D printers also offer printing with advanced materials with incredible resolution. Meaning you don’t have to sacrifice product quality to create custom, low-volume parts.

Virtual Inventory

Minimizing physical inventory and relying less on overseas supply chains has become an increasingly important practice for companies. Virtualizing inventory into 3D models that can be produced on demand is a solution to both problems. Physical inventory can be made in-house when needed rather than shipped in from overseas.

Technical Specifications

| Intamsys Funmat HT | |

|---|---|

| Printing Technology | Fused Filament Fabrication (FFF) |

| Machine Size | 543 x 501 x 663 mm (21.4 x 19.7 x 26.1″) |

| Build Volume | 260 x 260 x 260 mm (10.2 x 10.2 x 10.2″) |

| Build Platform | PI Sheet Heating + Ceramic Glass |

| Leveling | Automatic Leveling |

| Layer Thickness | 0.05 – 0.30 mm |

| Max Travel Speed | 300 mm/s |

| Max Extruder Temperature | 450°C (842°F) |

| Max Chamber Temperature | 90°C (194°F) |

| Max Build Plate Temperature | 160°C (320°F) |

| Input File Type | STL/OBJ |

| Filament Diameter | 1.75 mm |

| Position Resolution | XY: 12.25 µm Z: 1.25 µm |

| Motor Drive | High Performance Independent Drivers |

| Safety Certification | FCC, SGS, CE |

| Connectivity | WiFi, Ethernet, USB |

| Supported Materials* | PEEK, PEEK-CF, PEEK-GF, PEKK, ULTEM™ (PEI), PPSU, PC, PC Alloys, PA, PA-CF, ASA, ABS, HIPS, Carbon-Fiber Filled, Glass-Fiber Filled, ESD-Safe, and more |

*Results of part printing may vary depending on material and/or design and size of the printed part.

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

Bambu Lab Heatbed Surface Magnet (with Cutout) – P1 Series Bambu Lab

3D Printer Parts

3D Printer Parts