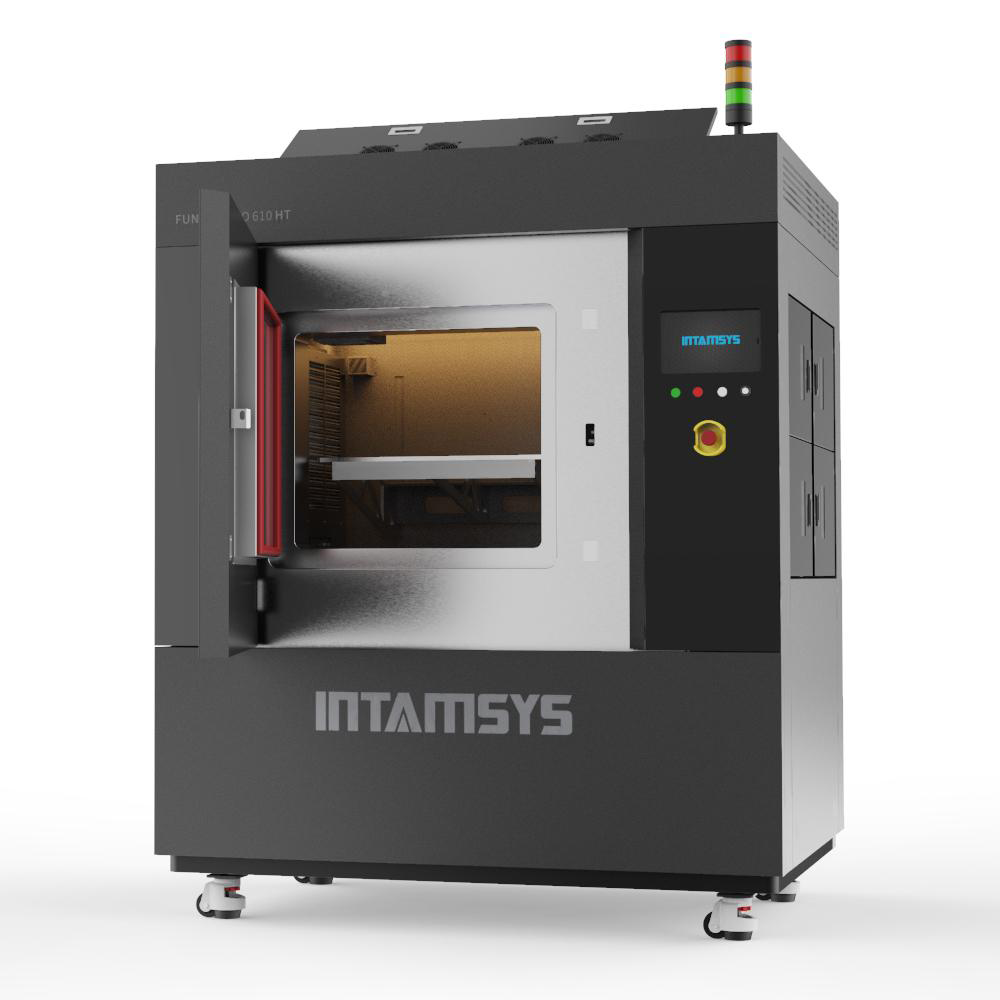

Intamsys Funmat Pro 610 HT 3D Printer Intamsys

$ 124.995,00 $ 31.248,75

Intamsys Funmat Pro 610 HT

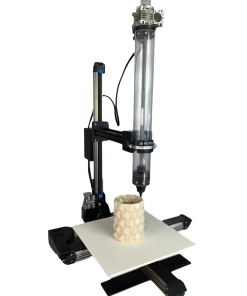

Large Volume Industrial 3D Printer

The Intamsys Funmat Pro 610 HT unlocks the potential of industrial-grade, high-quality 3D printing. With a 610 x 508 x 508mm build volume, the Funmat Pro 610 HT is Intamsys’ largest and most feature-packed 3D printer.

The Funmat Pro 610 HT has a high-temperature thermal system that includes a 300°C constant chamber temperature and 500°C dual extruders with all-metal hot ends. With its dual high temperature extruders, the Funmat Pro 610 HT is ideal for printing large, high-performance materials such as PEEK, PEKK, ULTEM™(PEI), PPSU, and much more.

The Next-Generation in Large Scale FFF Printing

Industrial 3D printing technology enables customers to print functional prototypes, tooling and end-use parts that optimize the entire design to manufacturing process. 3D printing technology has enabled customers to print end-use parts that are both lighter and stronger, while creating tools that have pushed the boundaries of industrial applications. The aerospace and automotive sectors have been huge benefactors of 3D printing as well as early adopters of the end-use capabilities that 3D printing now provides.

INTAMSYS is paving the way with their breakthrough Funmat Pro 610HT. Unlocking the potential of industrial-grade, high-quality 3D printing, equipped to effectively handle the tough requirements needed to print with high-performance thermoplastics.

Key Features & Benefits

High Print Quality

Optimized 3D printing environment with an advanced servo control system provides you with premium print quality.

Production Level Size

A large build volume of 610 x 508 x 508mm (24 x 20 x 20″) allows you to print large parts or multiple small parts for low volume production.

Advanced Thermal Design

Specialty high-temp nozzles and chamber heat up to 500°C and 300°C respectively, unlocking advanced material use and solving part warpage.

Best-in-Class Safety

Equipped with best-in-class safety components. CE (EMC/RED/LVT) certified for industry-grade application standard.

Advanced Material Support

The Funmat Pro 610HT can support almost every high-performance thermoplastic material available on the market including PEEK, PEKK, PAEK, ULTEM™, PPSU, PC, PA, ASA, ABS and others. This is made possible through the 610HT’s dual, liquid-cooled hotends capable of printing at 500°C. The heated chamber can also reach 300°C in order to give you premium print quality without warpage or delamination. Now you can print super strong parts with ease for functional prototypes and small volume production.

High Precision Customization & Production

Additive Manufacturing and 3D printing is an incredible tool to create custom-made, high-precision parts at much lower costs than traditional manufacturing methods. You no longer need manufacturing runs in the thousands. With 3D printing you can have production runs of only a single part with low to no added fixed costs. The Intamsys Funmat Pro 610 HT can enable this low volume custom production with incredibly strong thermoplastics with high precision.

The Funmat Pro 610 HT 3D printer is incredibly precise with a dimensional accuracy of ±0.15 mm per 100 mm. This enables you can create incredibly precise and complex structures that aren’t possible with traditional subtractive manufacturing processes like CNC milling.

Dual Extrusion Supports Complex Models

With high-temperature dual extrusion, the Intamsys Funmat Pro HT can create intricate and complex parts using purpose-made support materials that easily break away from printed parts or can be dissolved in water or other solutions. This allows you to create parts that aren’t possible with traditional manufacturing methods quickly and easily.

Combining this with the advanced material support of the Funmat Pro 610 HT allows you to create parts that are lighter and potentially even stronger than traditionally manufactured parts. It also allows a more efficient usage of materials with minimal material waste.

Open Material System with Infinite Possibilities

Intamsys is committed to providing the best 3D printing experience to customers, so they developed their own industrial filament solutions designed specifically for printing with the Intamsys Funmat line of 3D printers. In order to truly fulfill their mission of providing the best 3D printing experience possible, the Funmat Pro 610HT has an open-source filament system. This means you can use any 1.75mm filament available on the market. Now you can experiment with cutting edge materials, or limit costs by shopping around.

Technical Specifications

| Intamsys Funmat Pro 610HT | |

|---|---|

| Printing Technology | Fused Filament Fabrication (FFF) |

| Machine Size | 1,710 x 1,390 x 2,080 mm (67.3 x 54.7 x 80.1″) |

| Machine Net Weight | 1,450 kg (3,197 lbs.) |

| Build Volume | 610 x 508 x 508 mm (24 x 20 x 20″) |

| Build Platform | Vacuum Absorption |

| Leveling | Automatic Leveling |

| Layer Thickness | 0.15 – 0.30 mm |

| Max Travel Speed | XY: 400 mm/s Z: 50 mm/s |

| Print Nozzles | 2 scratch-resistant nozzles |

| Max Extruder Temperature | 500°C (932°F) |

| Max Chamber Temperature | 300°C (572°F) |

| Max Filament Chamber Temperature | 50°C (122°F), with dry compressed air (external air compressor required) |

| Input File Type | STL/OBJ |

| Filament Diameter | 1.75 mm |

| Position Resolution | XY: 12.5 µm Z: 1.25 µm |

| Motor Drive | High Precision Servo System |

| Smart Monitor & Control | Auto-Cleaning Nozzles, Filament Jam Warning, Filament Absence Warning, Liquid Cooling System, Vacuum Absorption Platform, Over Heat Protection, Automatic Filament Reloading |

| Safety Certification | FCC, CE |

| Connectivity | WiFi, Ethernet, USB |

| Supported Materials* | PEEK, PEEK-CF, PEEK-GF, PEKK, ULTEM™ (PEI), PPSU, PC-HT, PC, PC Alloys, PA-HT, PA, PA-CF, ASA, ABS, HIPS, Carbon-Fiber Filled, Glass-Fiber Filled, ESD-Safe, and more |

*Results of part printing may vary depending on material and/or design and size of the printed part.

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

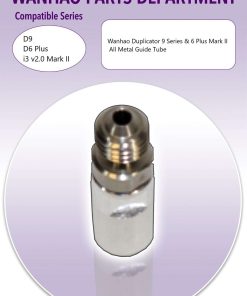

All Metal Guide Tube – Wanhao D9/D6Plus Mk2/i3Plus Mk2 Wanhao Precision Casting Co., Limited

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts