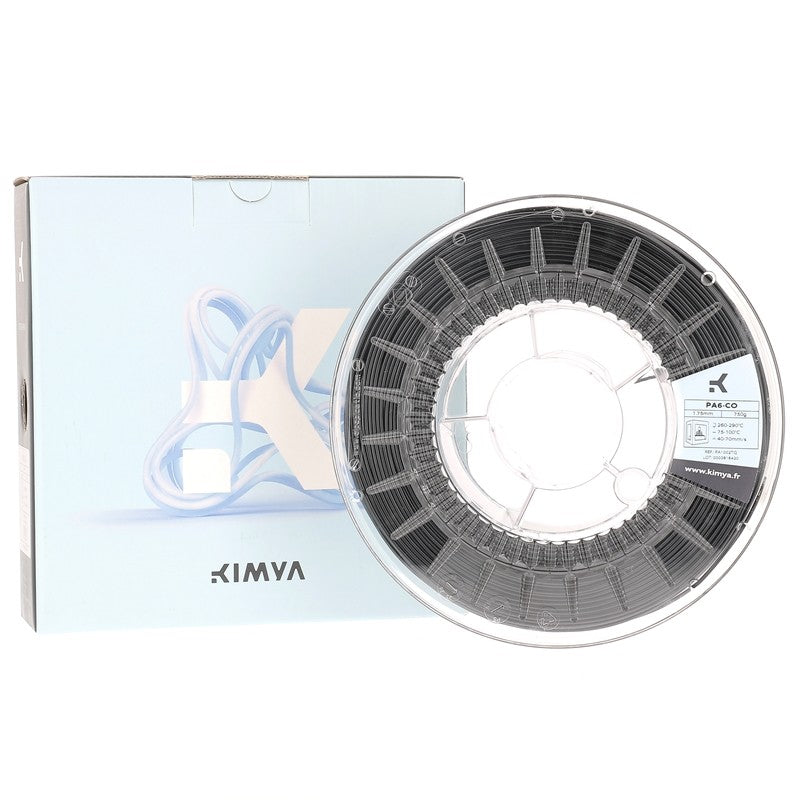

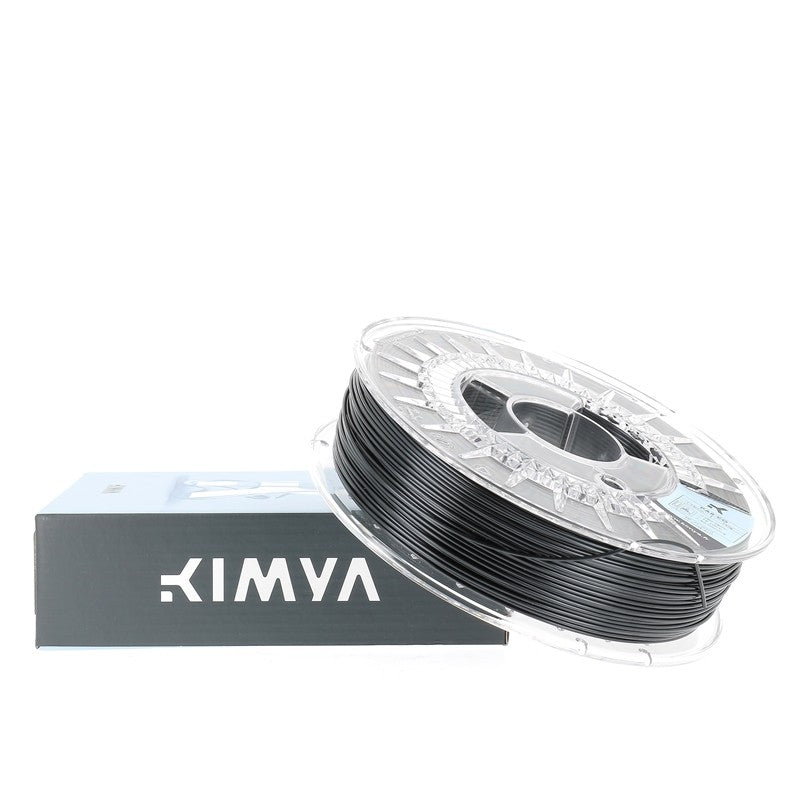

KIMYA – PA6-CO Filament – Black Armor Group

$ 81,40 $ 40,70

Kimya PA6-CO Filament 3D

The Kimya PA6-CO filament is a co-polymer based on a Nylon 6 grade. This unfilled polyamide has excellent tensile strength and very low warping behavior. Unlike other polyamide filaments on the market the PA6-CO is very easy to print and can be used seamlessly on open chamber 3D printers. It is the perfect standard polyamide go-to thanks to its inherent polyamide properties of high mechanical, chemical and heat resistance. Due to the general moisture sensitivity of polyamides, the filament must be dried before printing.

- Excellent printablilty even with open chamber printers

- Low warping

- Good wear resistance

KIMYA’s New PA6-CO

Polyamides are the largest group of engineering thermoplastics. They are mainly used for technical applications thanks to their good mechanical properties (traction, fatigue, low friction) and their resistance to the action of numerous chemical products (oils, greases, hydrocarbons, fuels, aldehydes, ketones, esters, etc.).

Properties of PA6-CO

Polyamides are the largest group of engineering thermoplastics. They are mainly used for technical applications thanks to their good mechanical properties (traction, fatigue, low friction) and their resistance to the action of numerous chemical products (oils, greases, hydrocarbons, fuels, aldehydes, ketones, esters, etc.).

Polyamides are polymers composed of carbon, oxygen and nitrogen (amide functions) that come in several grades depending on the number of carbon atoms that make up their monomer. Kimya PA6-CO is a co-polymer, i.e., it is composed of at least two types of polyamides. Kimya has combined the properties of PA6, universally recognized for its robustness, with other polyamides to improve its compatibility with the FDM additive manufacturing process: reducing warping, limiting moisture absorption, etc.

The Kimya PA6-CO filament is the ideal alternative if you wish to print parts with good mechanical characteristics, thermal stability, and chemical inertia without the need to use a heated printer. Using Kimya PA6-CO filament, manufacturers can now take advantage of the FDM technique to produce 3D polyamide parts such as air supply systems, filtration systems and automotive cooling systems.

Technical sheets

Filament Physical Properties

| Properties | Testing Methods | Values |

|---|---|---|

| Diameter | INS-6712 | 1.75±0.1mm 2.85±0.1mm |

| Volumic Mass | ISO 1183-1 | 1.157 g/cm3 |

| Glass transition temperature (Tg) | ISO 11357-1 DSC (10°C/min – 20-300°C) | 65°C |

| Melting temperature (Tf) | ISO 11357-1 DSC (10°C/min – 0-300°C) | 227°C |

Specimen Print Settings

| Print axis | XY |

|---|---|

| Print speed | 55mm/s |

| Filling | 100% – straight |

| Fill angle | 45°/-45° |

| Nozzle temperature | 270°C |

| Tray temperature | 75°C |

Properties of Specimen Printed with Filament

| Properties | Testing Methods | Values | |

|---|---|---|---|

| Mechanical Properties | Modulus of elasticity in tension | ISO 527-2/5A/50 | 2166MPa |

| Tensile strength | ISO 527-2/5A/50 | 56.1MPa | |

| Deformation at tensile strength | ISO 527-2/5A/50 | 4.3% | |

| Deformation at tensile strength | ISO 527-2/5A/50 | 4.3% | |

| Tensile stress at break | ISO 527-2/5A/50 | 13.4MPa | |

| Elongation at break in tension (type A) | ISO 527-2/5A/50 | <14% | |

| Modulus of elasticity in bending | ISO 178 | 2017MPa | |

| Bending strain at break | ISO 178 | <5% | |

| Bending stress at conventional deflection (3.5% strain)* | ISO 178 | 65.9MPa | |

| Charpy impact strength | ISO 179-1/1eA | 3.9kJ/m² | |

| Shore hardness | ISO 868 | 77.3 |

Certifications and Uses

3D Printing Profile

| Properties | Manufacturer Rating |

|---|---|

| Ease to print | 4 / 5 |

| Rigidity | 4 / 5 |

| Impact Strength | 2 / 5 |

| Sensitivity to moisture | 4 / 5 |

| Temperature resistance | 2 / 5 |

| Weather Resistance | 3 / 5 |

| RoHs | Compliant |

| EU 10/2011 | Non Compliant |

| FDA | Non Compliant |

| UL94 – V0 | Non Compliant |

| ESD Protection | Non Compliant |

Miscellaneous

3D Printing Profile

| Setting | Recommendation |

|---|---|

| Extrusion Temperature | 260 – 290°C |

| Plate Temperature | 75-100°C |

| Printing speed | 40-70mm/s |

| Diameter | 1.75mm, 2.85mm |

|---|---|

| Color | Black |

| Spool Size | 750g |

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer