Phrozen EL400 Elastomer Resin – 1KG Phrozen

$ 119,99 $ 48,00

Phrozen EL400 Elastomer Resin – 1KG

Pre-Order: Will begin shipping from the manufacturer in late July 2024.

Creating prototypes with elastomer materials used to be tedious and time-consuming in traditional manufacturing methods. Phrozen EL400 Resin changes the game with its rubber-like, highly elastic, and tear-resistant elastomer properties, opening new possibilities for rapid iterative prototyping in 3D printing.

It’s ideal for creating rubber-like prototypes like grips, seals, and gaskets or simulating lattice structures used in midsoles, saddles, and cushioning. Opening new possibilities for rapid iterative elastomeric prototyping that very difficult to achieve with traditional method (like injection molding).

- Medium Hardness With High Elasticity: With shore hardness of 70-75A and 391% elongation, EL400 offers the optimal blend of elasticity and toughness for printing production-grade elastomer prototypes.

- Tear-Resistant: Elastomeric prototypes printed with EL400 can endure over 60,000 cycles (Ross Flexing Fatigue test at 23°C) without tearing apart. Test your prototype performance in real-world scenarios since initial design stage.

- Great Rebound Resilience : Comes with higher rebound resilience compared to most resins in the market. Each printed elastomer will effectively return to its original shape after initiated deformation.

Precautions

- Make sure to preserve resin at room temperature. Store in dark and ventilated conditions.

- After printing, please keep used resins in a closed & opaque bottle.

- Avoid mixing used resin with new resin.

- Keep resin away from kids and away from direct sunlight exposure.

- Wear gloves and masks when using resins.

- If this chemical contacts the skin or eye, wash with plenty of water. DO NOT dump resin.

- Please cure it and treat it as general plastic garbage.

Phrozen EL400 Elastomer Resin Specs

- Weight: 1kg per bottle (Gray)

- Density: 1.04 g/cm³

- Viscosity (@25°C): 2300-3000 mPas

- Surface Hardness: 70–75 Shore A

- Tensile Strength at Break: 6.3 MPa

- Tear Strength: 22 KN/m

- Elongation at Break: 391%

- Ross Flexing Fatigue (23℃, 60° bending, 100 cycle/minute): >60,000 cycles

- Bayshore Rebound Resilience: 40%

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Resin

Phrozen Aqua Hyperfine 3D Printing Resin – Graphite – 1KG Phrozen

3D Printer Resin

Phrozen Aqua Hyperfine 3D Printing Resin – Blue – 1KG Phrozen

3D Printer Accessories

3D Printer Parts

LCD Driver Board Ribbon Cable for Regular Phrozen Shuffle PHROZEN

3D Printer Accessories

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

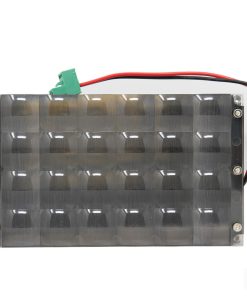

LCD Driver w/ Flat Cable, MIPI Board – Phrozen Shuffle 2019 PHROZEN

3D Printer Parts

3D Printer Parts

Phrozen – Sonic Mighty 8K / Mighty 12K – 10″ Build Plate PHROZEN

3D Printer Parts

Aluminum Vat With FEP Pre Installed – Phrozen Transform Fast PHROZEN

3D Printer Parts

3D Printer Resin

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Accessories

3D Printer Parts

3D Printer Parts

3D Printer Parts

Phrozen 8.9″ MonoChrome LCD Screen Panel for Sonic XL 4K PHROZEN

3D Printer Parts

Phrozen Aluminum Vat w/ FEP Installed – XL Series Printers PHROZEN

3D Printer Accessories

3D Printer Parts

3D Printer Parts