Polymaker PolyDryer Polymaker

$ 79,99 $ 39,99

Polymaker PolyDryer

When drying meets storage. A new standard in filament care!

PolyDryer™ is your ultimate 3D filament drying & storage solution which protect against dust and moisture. Printing with wet 3D filament can lead to various issues, such as stringing, clogging and rough or poor surface quality, especially noticeable during high-speed printing.

PolyDryer™, featuring modular design, superior sealing and optimized drying system, ensures quick and even drying with its Dry Dock, whilst offering the dual function with its PolyDryer™ Box as a 3D filament dry box.

Dry and store in one solution

With one drying dock you can add as many PolyDryer Boxes as you need so your next project is always ready to go.

You’ll never have to break the seal again

Don’t worry about moisture ruining your prints, the PolyDryer box has the best sealing performance on the market.

Brings your forgotten spools back to life

360 degree airflow secures even drying of your spool without damaging it. Compatible with all the popular 3D printing materials with 3 preset power levels.

Dry & Store

All in one solution With one drying dock you can add as many PolyDryer Boxes as you need so your next project is always ready to go.

Superior Sealing

You’ll never have to break the seal again Don’t worry about moisture ruining your prints, the PolyDryer Box has the best sealing performance on the market.

Efficient Drying

Brings your forgotten spools back to life 360° airflow secures even drying of your spool without damaging it. Compatible with all popular 3D printing materials with 3 preset power levels.

Continuous Drying

Continuous filament drying as needed during storage, eliminating concerns about humidity absorption.

Versatile Size

Compatible with various spool sizes up to 1 kg, featuring a central holder for smooth rotation.

Printable Add-ons

Personalize with printable add-ons for hanging or connecting them together.

Colored Desiccant

Color-changing desiccant: monitor filament environment effortlessly.

FAQ

Why are there only power levels but not temperature?

The 360° drying system creates a temperature distribution inside the PolyDryer™. For that reason, a single temperature can’t represent the true situation as it varies around the spool. Other elements like the room temperature, initial moisture content, spool size, and material type and weight also affect the internal temperature of the box.

How do I know what setting should I use?

The sticker on the dry dock lists all suitable power levels for most common materials. In general, using higher power level and longer drying time can achieve better drying result. If you are using materials from other brands, please check the softening temperature of the filament first before using a higher power level.

What spools can fit inside the PolyDryer™?

The maximum capacity of PolyDryer™ box is 205 Φ * 78(H) mm. This means all 1kg spools or less from Polymaker can fit in the PolyDryer™ and most 1kg spools or less from the other brands can fit in the PolyDryer™. For smaller spools use the internal spool roller for a better experience.

How long can materials stay dry in the PolyDryer™ Box?

The PolyDryer™ Box was designed with excellent sealing and silica gel desiccant to extend your filament storage time. In our internal experiment( an environment of 20℃ and 60% RH), the humidity inside the PolyDryer™ Box changed less than 5% in 30 days. In a comparison test the sealing capability of the PolyDryer™ Box is ~1.5 times that of a DIY storage box.

Can I print and dry at the same time with PolyDryer™?

Yes, the PolyDryer™ has a continuous drying mode. Materials can be either pre-dried on the PolyDryer™ before printing or the PolyDryer™ can be set to continuous drying mode for drying while printing.

Why does the silica gel change color to pink during drying?

As the hot air removes moisture from your material, the silica gel desiccant helps out by soaking up some of that moisture, making the drying process even more efficient. After a while, you might notice some of the pink desiccant turning back to blue, especially when drying on power level 3. This change is a good sign as it means there’s less moisture inside the PolyDryer™ Box, and the hot air is doing a great job of drying both your material and the silica gel desiccant at the same time. It’s PolyDryer™ Box, letting you know that everything’s working just as it should! The silica gel has been certified safe.

What is continuous drying mode for?

For best results seal the PolyDryer™ box with the airlocks as soon as the drying cycle has finished. If you aren’t able to do this, continuous mode continues to dry the filament until you’re able to reseal after a drying cycle. And continous drying mode will not stop until you turn it off.

| Product: | PolyDryer (Dryer Dock + Storage Box), Storage Box Only |

|---|

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

3DFS – Compatible Enclosure with HEPA Cover For UltiMaker S3 3DFS

3D Printer Accessories

3D Printer Accessories

Magigoo Pro PP – 3D Bed Adhesion Solution for Polypropylene Magigoo

3D Printer Accessories

Magigoo Pro PPGF – For Glass Reinforced Polypropylene Magigoo

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

Magigoo Pro PC – 3D Bed Adhesion Solution for Polycarbonate Magigoo

3D Printer Accessories

Glue stick – 3D printer part Wanhao Precision Casting Co., Limited

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

3D Printer Accessories

GOODWAY Performance Explosion Proof Industrial HEPA Vacuum Goodway

3D Printer Accessories

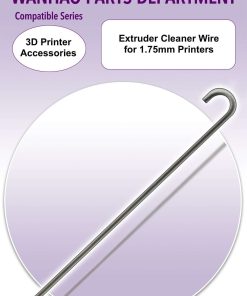

Extruder cleaner wire for 1.75mm printers Wanhao Precision Casting Co., Limited

3D Printer Accessories

BlazeCut T-Series Fire Suppression for Devices: T100E BlazeCutUSA

3D Printer Accessories

3D Printer Accessories

.4MM drill cleaning tool for 3D nozzle cleaning Wanhao Precision Casting Co., Limited

3D Printer Accessories

Magigoo Pro Metal – For Ultrafuse 316L Metal Filament Magigoo