Shapeoko 5 Pro CNC Router Carbide 3D

$ 3.750,00 $ 937,50

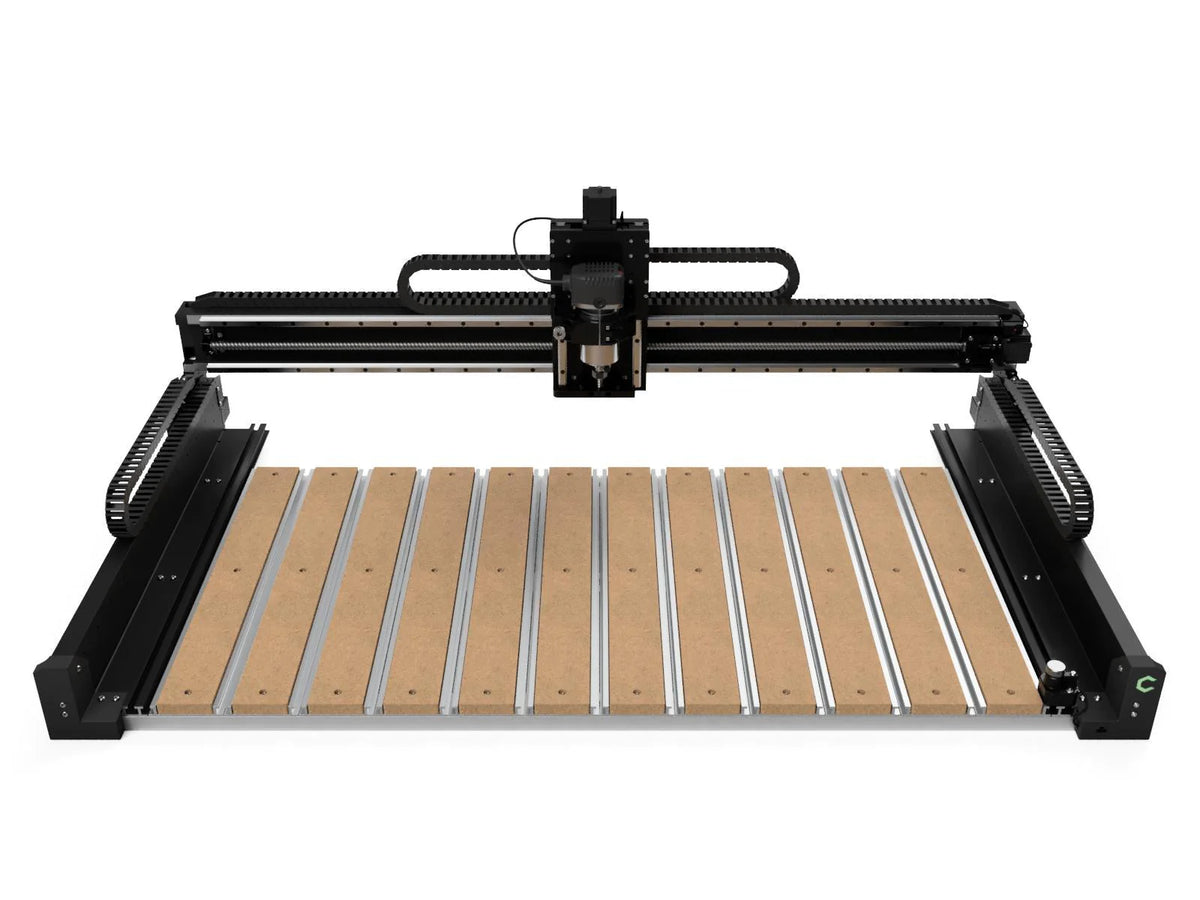

Shapeoko 5 Pro CNC Router

Rigid, Accurate, & Reliable

Shapeoko 5 Pro uses hardened linear rails and ballscrews for increased productivity and accuracy. It was built to run all day, every day, giving you maximum productivity and profit.

At up to 4 feet in width, Shapeoko 5 Pro is bigger than ever, so you can take on larger jobs or nest more parts together and run the machine longer.

Shapeoko 5 Pro is not just a CNC Router, it’s a complete system of hardware, software, accessories, and training, built and supported in the USA, that will get you up and running as fast as possible.

Use Almost Any Material

Shapeoko is a true multi-material machine that works with just about any material you want.

Wood

Cut any type of wood, from the softest pine to the hardest white oak. You pick whatever is right for your project, and Shapeoko 5 Pro will cut it.

Plastic

Cut any common plastic, including: Acrylic, ABS, HDPE, Delrin, PE, PP, PEEK

Aluminum

Use a quality carbide cutter, and you’ll be able to cut aluminum as easily as wood (just a little slower).

Brass

Brass is an excellent material for many projects. Jewelry, nameplates, branding irons, inlays, and small handles and catches can all be made directly on your Shapeoko 5 Pro to make your projects truly unique.

Wax, Foam, and More

Harder foams, waxes, and polyurethane tooling board all cut easily.

Stone and Ceramic

Ceramics and stone don’t cut well, but you can still use them in your projects. Engrave them with the Mc Etcher Drag Engraver.

Make Any Type of Cut

Cut Profiles

Simple 2D profiles are the most basic type of cut, and they’re easy with Shapeoko. The Carbide Create CAD/CAM software makes it easy to pick a vector and optionally add tabs to your parts to keep everything connected.

Cut Pockets

Pockets are tough without a CNC machine. Normally you’d have to freehand them with your router or make a template for the router to follow. Shapeoko and Carbide Create make it easy to pick a depth and a contour to follow.

Inlays

Inlays add a ton of detail to your products, but they’re tough to do by hand. With the accuracy of Shapeoko 5 Pro, you’ll be able to make inlays that fit perfectly and with detail that cannot be made by hand.

V-Carving

V-carving takes advantage of the 3-axis motion of Shapeoko 5 Pro to quickly create engraved features that give your projects real depth.

Engraving

Use Carbide 3D engraving bits to mark tiny details into plastic and metal parts.

Drag Engraving

Drag engraving, using the McEtcher, is a great way to add detail to stone, ceramics, hard plastic, and anodized aluminum.

Fine Details

Even though it’s a large machine, Shapeoko 5 Pro is capable of cutting parts with great detail, from tiny pockets to fine engraving.

3D Carving

When you’re ready for more advanced projects, you can upgrade to the Carbide Create Pro software to generate full 3D projects, either of your own designs or using files from a third party.

Shapeoko is a Complete CNC Experience

CNC machines that are missing critical parts are frustrating and expensive. They cause you to spend time and money completing a machine you bought to make parts. We never want to put a customer through that, so the Shapeoko 5 Pro is a complete package with everything you need to get started.

After all, you’re buying a CNC router to complete your projects, not to turn the machine itself into a project.

Workholding

Shapeoko 5 Pro is based on the Hybrid Table that includes T-slot workholding and a set of clamps to go with it.

Workholding is one of the most challenging parts of CNC, and the Hybrid Table gives you more options than any other system.

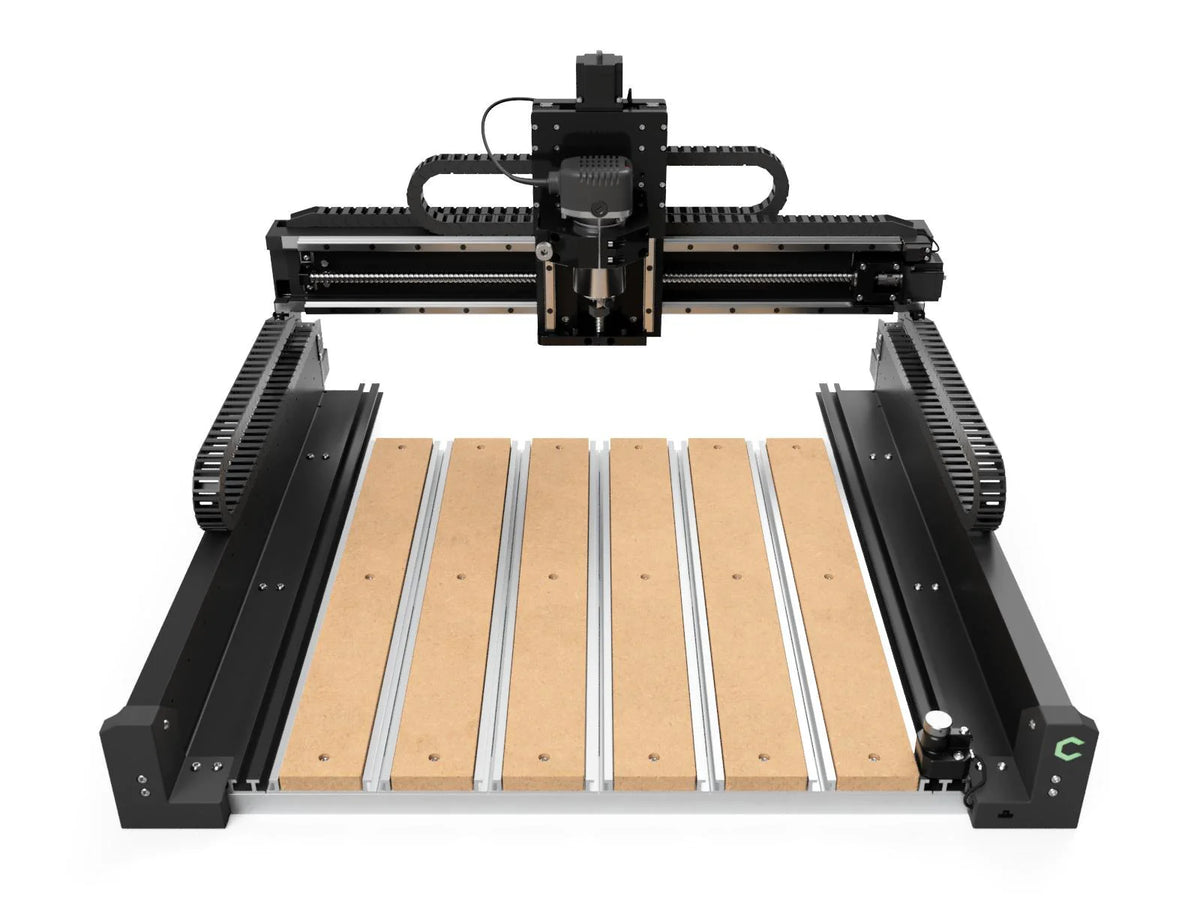

Fit Full-Sized Sheets

Shapeoko 5 Pro is available in 2 and 4-foot widths, so you can fit standard-sized sheets into the machine without cutting them. There’s additional room on either side for clamps to hold everything in place.

The machine is open front-to-back, so you can index larger sheets through the machine.

BitSetter

Shapeoko 5 Pro includes BitSetter, our system to make tool changes a breeze using a combination of custom hardware and software.

We created BitSetter years ago for our original Nomad Desktop CNC Mill, and it’s been a staple of Carbide 3D machines ever since.

Power Pendant

The Power Pendant remotely controls the power to the machine as an emergency stop and gives you a feedhold button if you just want to pause the program.

It’s mounted on a 2-meter tether from the electronics, so you can mount the pendant somewhere that’s easy for you to reach.

Lighted Gantry

Shapeoko 5 Pro includes LED lighting under the gantry to make it comfortable and easy to see your work.

Dust Collection

You don’t want dust and chips getting into precision mechanical parts so dust collection is critical for a CNC router. Carbide 3D includes their Sweepy V2 Dust Boot as a simple and effective way to keep your machine clean.

You provide the shop vacuum, and we’ve got the rest covered.

Gantry Shift for Joinery

If you need to tip up a board for joinery work, like tenons or dovetails, you can shift the gantry forward by 3.2″ to give you the clearance you need over the front edge of the table.

Accessory Mount

We know people like to accessorize their machines so we built a custom accessory mount directly into the router mount.

Sweepy Pro (Optional)

If you prefer a fixed Z dust boot, we built the new Z-axis to work with Sweepy Pro.

Video Training Library

You’ll have aceess to a 5-hour video training library that covers everything from how to run your Shapeoko, how to use the design software, and five projects to get you started.

One-on-One Training

Your machine comes with 4, 30-minute video sessions with a Carbide 3D expert to help you get started.

Carbide 3D will help you get your machine set up, teach you how to use Carbide Create, and/or answer any questions you have about your machine.

30-Day, Mistakes are on Us

For the first 30 days that you own your machine, Carbide 3D will replace or repair any Carbide 3D-branded item that gets damaged, even if it’s your fault!

This is in addition to their standard one-year warranty on all parts and electronics.

They want you to get up and running quickly, without fear. Learn more here.

CAD/CAM Software is Included

All Carbide 3D machines include Carbide Create, a full-featured 2D design and machining program, saving you hundreds of dollars on third-party software.

Whether you’re starting from a blank page, or loading a design from the web, Carbide Create has everything you need for your projects. It also comes with a comprehensive video training library to get you up and running quickly.

Carbide Create runs on your Windows or Mac computer and you can install it on as many computers as you need to.

Do you have your own CAD/CAM software? No problem, our machines also accept standard G-code so you can use any software you like.

No Finger Pointing!

Aside from the lost time and money, the worst thing about piecing together a CNC router from multiple vendors is that there’s now nobody to speak with if you need help- they’re all going to point to the other company.

By selling you a full machine and the software to go with it, we’re able to help you troubleshoot any problems you have. We’ll even help you with project-specific problems to get you started.

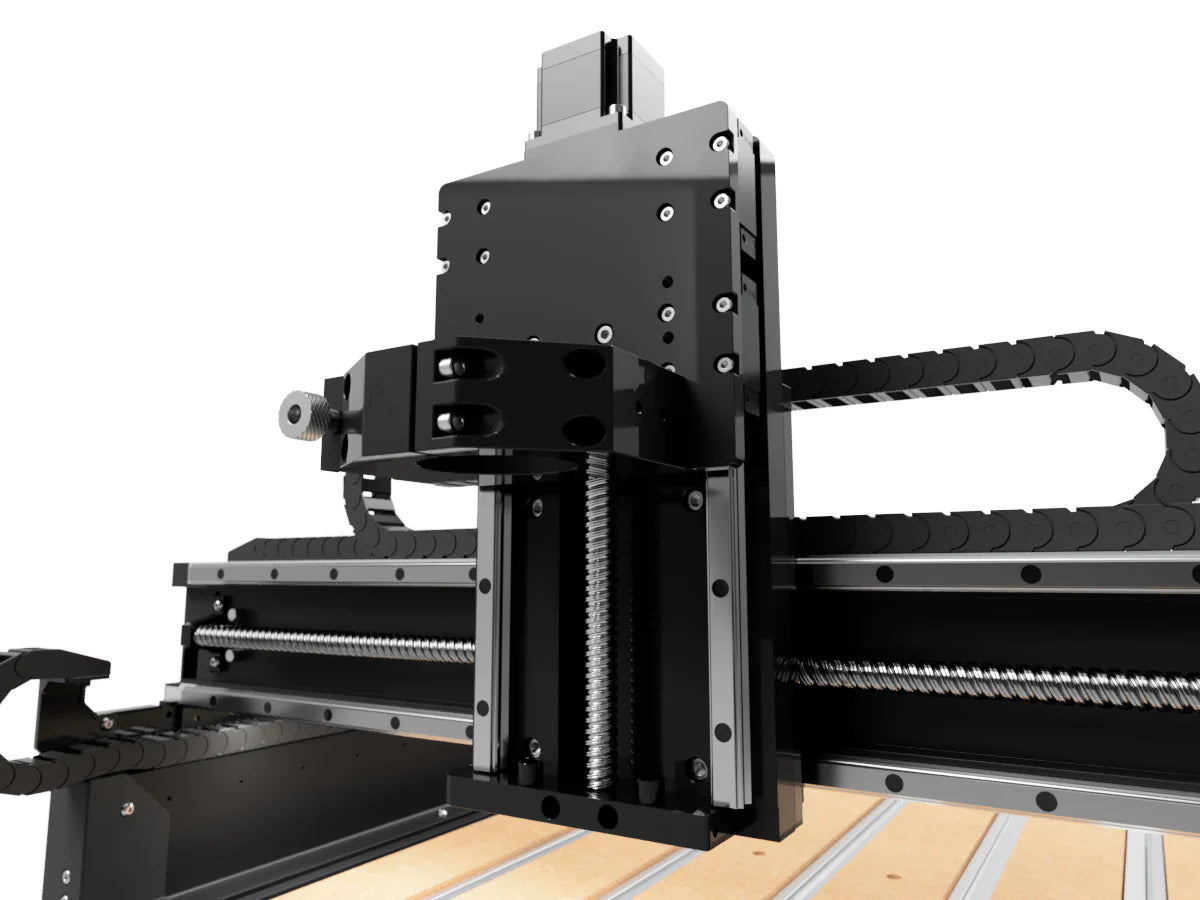

High-Performance, Heavy-Duty Motion System

Shapeoko 5 Pro is built from a rigid base, custom extrusions, linear rails, and ballscrews. No round rails, nothing unupported, no belts, leadscrews, or gear racks. You can push the machine harder and get more accurate parts than ever before.

Hybrid Table

Shapeoko 5 Pro is built up from our Hybrid Table. In additonal to being a great workholding system, the Hybrid Table gives the Shapeoko 5 Pro a solid foundation on which to build the rest of the machine.

HG-15 Rails

Shapeoko 5 Pro uses HG-15 linear rails on every axis. These rails are built for much larger, heavier machines and they give the Shapeoko 5 Pro its fantastic performance.

The HG-15 rails are sealed and plugged to keep dust away from the bearings themselves, so you get maximum durability in a rough environment.

Ballscrews

On the X and Y-axis we use 16mm ballscrews with a 20mm pitch to ensure that we maintain the rapid movement that Shapeoko has always been capable of while adding a ton of rigidity.

The ballscrews include custom-made wipers to remove as much dust as possible to keep your machine working for a long time.

Ballscrew Mounts

Where the ballscrews mount to the machine, we use two angular-contact ball bearings to keep backlash, or any other movement, to a minimum

HDZ Z-Axis

For the Z-axis we use a 1610 ballscrew so that the machine can easily lift a heavy 80mm spindle. In fact, the entire Z-axis was taken from the Shapeoko HDM, and it’s the beefiest Z-axis we’ve ever made.

Fully Supported Rails

We mount our rails to custom extrusions designed to support the entire length of the rail.

You won’t see deflection or twist as the machine moves, so you’ll get cleaner cuts with less chatter.

Precision Machined Extrusions

We don’t mount motion hardware to T-slots.

All of our extrusions are precision-machined in-house on industrial machining centers for maximum accuracy.

Optically Isolated Electronics

Our latest generation of electronics are optically-isolated and now uses a high-quality internal power supply to keep as much noise out of the system as possible.

Spindles and Routers

Shapeoko Pro 5 uses a trim router as a spindle. We recommend the Carbide Compact Router, but any router with a 65mm diameter, like the Makita RT0701C, will work.

The Carbide Compact Router is designed for 110V operation, so if you’re in a country with 220V power, you should grab a Makita RT0700C locally.

If you’re looking for more power, you can upgrade to the Carbide VFD Spindle.

What’s Included?

- Shapeoko 5 Pro CNC Machine

- T-Slot Hybrid Table

- Shapeoko 5 Pro BitSetter

- Carbide Motion control software

- Carbide Create 2D CAD/CAM software

- Assembly tools

- #201 .25″ Flat Endmill

- Qty 12, M6 Teez-Nutz T-Nuts

- Qty 6, Shapeoko Essentials Clamps

- Sweepy 65mm V2

- 4, 30 minute 1-on-1 training sessions with a Carbide 3D expert via video chat

What you need to provide

- 65mm trim router, either the Carbide Compact Router or VFD Spindle.

- Windows or Mac computer. (See specifications for computer requirements)

- Shop vacuum. (Optional but HIGHLY recommended)

Technical Specifications:

| Machine Specs | |

| Ballscrew X/Y | 16mm diameter, 20mm pitch with custom wiper |

| Ballscrew Z | 16mm diameter, 10mm pitch |

| Linear Rails | HG-15 |

| Homing Switches | Inductive sensors with Dual Y homing |

| Ballscrew Accuracy | +/- 50um per 300mm |

| Step Length X/Y | .012mm |

| Step Length Z | .006mm |

| Spindle Mount | 65mm Diameter |

| Total Z Travel | 6.1 in |

| Total Z Travel (With Sweepy Pro) | 5.51 in |

| Clearance from table to Z axis with Hybrid Table | 4 in |

| Clearance from table to Z axis without Hybrid Table | 5 in |

| Gantry Shift distance for joinery | 3.15 in |

| T-Slot Spacing | 4.04 in Center-to-center |

| Voltage | 110V or 220V, auto-switching |

| Amperage | 4A (Machine Only) |

| AC Plug | IEC C14 connector to NEMA 5-15P (Standard US plug) |

| 4×4 | |

| Machine Travel | 48.7 in(X) x 48.7 in(Y) |

| Machine Footprint | 60 in(X) x 59 in(Y) x 21 in(Z) |

| Shipping Box 1 | 60 in x 12 in x 16 in, 100lbs |

| Shipping Box 2 | 60 in x 12 in x 16 in, 110lbs |

| Size 4×2 | |

| Machine Travel | 48.7 in(X) x 24.53 in(Y) |

| Machine Footprint | 60 in(X) x 35 in(Y) x 21 in(Z) |

| Shipping Box 1 | 60 in x 12 in x 16 in, 110lbs |

| Shipping Box 2 | 37 in x 12 in x 17 in, 60lbs |

| Size 2×2 | |

| Machine Travel | 24.53 in(X) x 24.53 in(Y) |

| Machine Footprint | 35.5 in(X) x 35 in(Y) x 21 in(Z) |

| Shipping Box 1 | 36 in x 15 in x 12 in, 60lbs |

| Shipping Box 2 | 37 in x 12 in x 17 in, 60lbs |

| Computer Requirements | |

| Windows | Windows 10 or 11, 64-bit (Intel or AMD) |

| OSX | OS/X 10.14 or higher |

| Size | 4×4, 4×2, 2×2 |

|---|

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Accessories

CNC Accessories

CNC Machine

CNC Machine

CNC Parts

Laser Cutter Parts

Full Spectrum Laser Muse 3D 5.0″ ZnSe Focus Lens Full Spectrum Laser

CNC Parts

CNC Accessories

CNC Accessories

CNC Parts

CNC Machine

CNC Machine

CNC Machine