Slice Engineering Mosquito® Magnum+ Hotend – Liquid Cooled Slice Engineering

$ 374,99 $ 112,50

More than a Hotend, A New Modality

The Slice Engineering Mosquito® Magnum+ Hotend includes all of the industry-leading benefits of the Mosquito® hotend line, such as Bimetallic Heat Break™ technology, a 500 °C temperature rating, ability to print all filaments from basic PLA to medical-grade PAEK, and the rigid roll cage structure that enables Slice Engineering’s famous One-Handed Nozzle Change™

Key Benefits of the Slice Engineering Mosquito® Magnum+

Thermally Optimized

- Filament contacts the hot block directly for maximum heat transfer efficiency

- Enhanced structural strength, ideal for large format printers, and non-planar printing

- Print PLA up to 88 mm3/s and ABS up to 91 mm3/s*

- Boost speed without losing resolution†

- Tips the scales at just 30% heavier than a standard Mosquito®, but with 3.5x the output

Highly Configurable

- Choose air or liquid cooling options

- Select Ø1.75 or Ø2.85 filament

- Expandable heater capacity, up to 100W

- Redundant temperature sensor sockets

- Optional 500 °C-rated nozzle insulator

- Uses standard-length (12.5 mm) Vanadium™ and Bridgemaster™ nozzles for both Ø1.75 or Ø2.85 filament sizes

What is the Slice Engineering Mosquito® Magnum+?

One of the primary concerns with material extrusion based 3D printing (commonly referred to as FDM or FFF) is speed. While FDM is certainly faster than hand sculpting an object, it is slower than some traditional manufacturing methods on a per part basis. This is especially true for large parts. A large print could take 48 hours or more for a 3D printer to complete, assuming that the print is completed correctly the first time, and no rework is required!

So why is FDM so slow?

Answer: flow rate capacity (ability to melt and extrude filament fast enough) and kinematics (physical limitations of machine motion related to the mass of the print head). Previous attempts to overcome these limitations resulted in printing processes that traded quality and resolution for speed. Slice Engineering has eliminated that trade off through design by thermal optimization, simultaneously addressing the issues of flow rate, resolution, and mass.

Since entering the scene in 2018, Slice Engineering has led the global FDM industry in hotend technology development with the Mosquito®® and Copperhead™ product lines, and they have no plans of slowing down. The newly announced Magnum+™ hotend is the latest extension of the Mosquito® product line and is the first hotend designed from the ground up with industrial users and high flow needs in mind. Magnum+ is not just applying DIY techniques to extend the melt zone, but rather the development of an entirely new modality for high speed FDM printing, optimized around the melting characteristics of thermoplastics.

Other Magnum+ Hotend Configurations

Slice Engineering Mosquito® Magnum+ – Air Cooled

Check it out!

Bondtech LGX ACE Magnum+ Hotend

Check it out!

Bondtech LGX ACE Magnum+ Printhead

Check it out!

Dimensions & Weights

1.75mm – Liquid Cooled

- Size: 25.8mm x 25.1mm x 54mm (L x W x H)

- Weight: 112.8 g

2.85mm – Liquid Cooled

- Size: 25.8mm x 25.1mm x 54mm (L x W x H)

- Weight: 112.7 g

Assembly Instructions & STEP Files

Mosquito® Magnum+ Assembly Instructions

Download Mosquito® Magnum+ Liquid Cooled STEP File

Compatibility Warning

This Hotend is not compatible with the Bondtech DDX extruder for Creality.

Manufacturer’s Part Number:

1.75mm: B-MMP-HO-0226-1.7-liq

2.85mm: B-MMP-HO-0241-2.8-liq

| Filament Diameter | 1.75mm, 2.85mm |

|---|

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

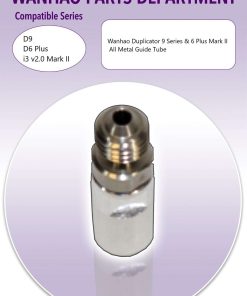

All Metal Guide Tube – Wanhao D9/D6Plus Mk2/i3Plus Mk2 Wanhao Precision Casting Co., Limited

CNC Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

CNC Parts