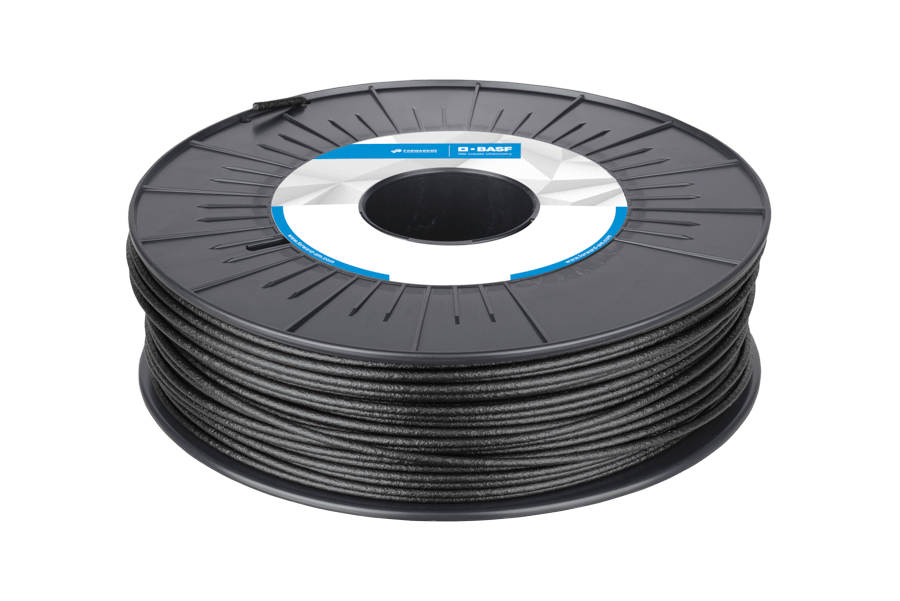

BASF – Ultrafuse PET CF15 Filament – Black M. Holland

$ 84,49 $ 42,24

Ultrafuse® PET CF15

Combines Easy Processability and very Low Moisture Uptake with Excellent Strength and Rigidity – at an Affordable Cost

Ultrafuse® PET CF15 is a polyethylene terephthalate reinforced with 15% carbon fiber. This engineering filament is easier to process than other carbon fiber reinforced filaments. Users will be able to 3D-print new components that remain fully functional under higher mechanical and thermal loads.

Description

Ultrafuse® PET CF15 is an engineering filament optimized to enable users to develop new 3D printing applications with higher requirements. With its superior heat resistance, high strength and rigidity, this is a filament for a wide range of demanding industrial applications. Its high dimensional stability and very low moisture uptake makes it a perfect solution for applications in humid operating environments.

Benefits at a Glance

- Strong, rigid components

- Easy to process

- Very low moisture absorption

- Heat resistant up to 108 °C

- High dimensional stability

- Compatible with BVOH and HIPS for support

- Excellent surface finish

Example Applications

- Automotive

- Jigs and fixtures

- Applications for humid operating environments

Material Properties

- Tensile Strength (MPa): 12.5 (ZX), 63.2 (XY)

- Flexural Modulus (MPa): 2253 (ZX), 6293 (XZ), 5452 (XY)

- Elongation at Break: 0.5 % (ZX), 3.7 % (XY)

- Impact Strength Izod notched (kJ/m2): 2.0 (XZ), 5.0 (XZ) 5.7 (XY)

- Impact Strength Izod unnotched (kJ/m2): 2.4 (ZX), 22.6 (XZ), 25.1 (XY)

- HDT at 0.45 MPa: 108 °C

Printing Guidelines

- Nozzle Temperature: 250-270 °C

- Build Chamber Temperature: –

- Bed Temperature: 65 – 85 °C

- Bed Material: Glass, PEI

- Nozzle Diameter: ≥ 0.6 mm, Ruby or hardened

- Print Speed: 30 – 80 mm / s

Next Steps

Printing Profiles

- Prusa

- BCN3D

- Donwload via Ultimaker website

- Download via Raise 3D website

Material Details

- Product Leaftlet

- Technical Data Sheet

- Safety Data Sheet

| Diameter | 1.75mm, 2.85mm |

|---|---|

| Spool Size | 750g |

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer