Bondtech DDX v3 For Creality CR-10(S)Pro/Max Bondtech SE

$ 142,00 $ 56,80

The Bondtech DDX Direct Drive eXtruder for Creality 3D printers is an upgrade kit that replaces the original bowden with a direct drive setup. It is a high-performance Dual Drive extruder based on the BMG Bondtech Mini Geared.

Multiple Hotends Compatibility

This model was created to be compatible with the original hotend of each Creality model. Users may also upgrade the hotend to Copperhead™ or Mosquito™.

The DDX v3 is much easier to install

With this integrated fan shroud and mount the DDX v3 is even easier to install.Snap the fan to the shroud without using screws. Adjust the height of the shroud with one front access screw.

Using a bed probe with DDX v3

The DDX was designed to allow space for the bed probe to be attached to the x-carriage. In models where there is no available space to attach a bed probe, like the BL Touch, to the X-carriage – CR-10 Max as example – a mount can be printed and attached to the right hand side of the DDX .

Bondtech DDX v3 Direct Drive eXtruder

This Direct Drive eXtruder from Bondtech is a high performance, high reliability 1,75mm Dual Drive extruder for Creality 3D printers, based on our very popular BMG. Bondtech’s unique Dual-Drive technology combined with either the factory hotend or for even better performance the industry leading hotends Copperhead™ or Mosquito™ from Slice Engineering, gives you a direct drive extruder with trouble free material feeding and enables the use of a wider range of materials. The housing parts are printed with PA12 (polyamide) for maximum strength and precision using industrial grade SLS technology.

Make your 3D printer even better

Bondtech DDX v3 Direct Drive eXtruder for Creality is designed to give the user more options – different materials; higher flow and/or wider nozzles; thinner layers – and achieve a higher print quality. The DDX v3 is based on the BMG Bondtech Mini Geared extruder featuring our unique Dual-Drive technology. The DDX v3 housing design provides an effective Hot-End cooling. With the 3:1 gearing ratio, high resolution prints with small nozzles or high flow prints with bigger nozzles can be achieved.

Easy To Setup

For ease of setup the kit is attached to the carriage with only 2 screws.

Product includes:

- 1x DDX v3 Extruder

- 1x Nema17 Pancake stepper motor

- 1x Thumbscrew Assembly

- 1x 70cm Stepper motor extension cable

- 1x 60cm PTFE tube

- 1x 7cm Capricorn tube

- 4x Zip-ties

- 3x M3x12mm screw

- 2x M3x20mm screw

- 1x M3x10mm button head screw

- 1x M3 square nut

- 1x 10079-4 PA12 Fan Shroud

- 1x 10079-44 SLS Bowden Adapter

(supplied with a tapered thread to better fit the stock metal threaded push-fit) - 1x M3x18 Screw

- 1x M3x20 Screw

- 2x M3x8 Screw

- 2x M3 5mm Square Nut

- 1x PTFE/Capricorn Cutting Fixture (FDM) NEW!!

Compatibility Table

Compatible with the following models:

- CR-10S Pro

- CR-10S Pro v2

- CR-10 Max*1

*1 Using DDX v3 on CR-10 Max

On the Cr-10 Max the z-height will be limited to in between 430mm and 455mm, instead of the original 470. This is due to the higher position of the push-fit on our extruder, that forces the bowden to bend at a lower level under the top bar. Use the Z(height) parameter at Machine Settings in the slicer to reflect this lower limit. Select the lower value and fine tune the max Z with testing.

THESE PARTS ARE REQUIRED FOR THE DDX TO FUNCTION PROPERLY

When assembling or disassembling your DDX extruder always keep the following elements and parts under watch. Ball bearings especially have the bad habit of sticking to the housing pockets, or falling off and getting lost.

Do not use your DDX without being sure you have ALL these parts.

Hinge and Secondary Drive Gear

The black plastic injected molded hinge holds the following parts:

- 1x 3x32mm shaft

- 1x 3x20mm shaft

- 2x needle bearings

- 1x Secondary drive gear

Main Shaft Assembly

The main shaft assembly holds the following parts:

- 1x Integrated main drive gear and shaft

- 1x black main double gear

- 2x 5x8x2.5mm ballbearing

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Parts

Aluminum Vat With FEP Pre Installed – Phrozen Transform Fast PHROZEN

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

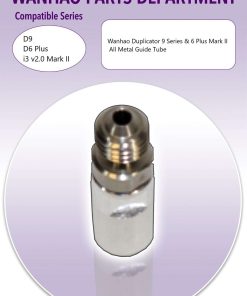

All Metal Guide Tube – Wanhao D9/D6Plus Mk2/i3Plus Mk2 Wanhao Precision Casting Co., Limited

3D Printer Parts

CNC Parts