KIMYA – PA Carbon Armor Group

$ 79,20 $ 39,60

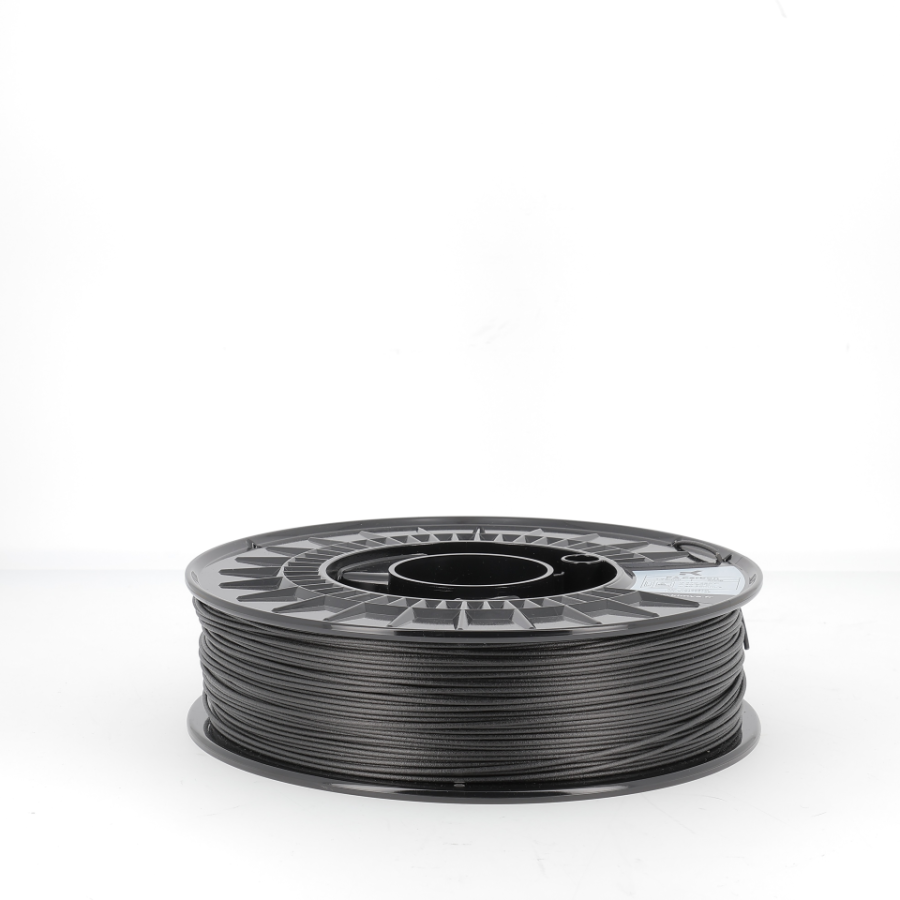

Kimya PA Carbon

Note: Spools will be ready for orders in September

In the dynamic world of 3D printing, finding the right material that balances strength, stability, and ease of use can be a game-changer. Enter the Kimya PA Carbon, a nylon-based filament reinforced with carbon fibers, designed to meet the rigorous demands of high-performance applications. This engineering thermoplastic stands out due to its exceptional mechanical properties, making it an ideal choice for creating parts that require high strength and durability.

Features

Exceptional Mechanical Properties:

Kimya PA Carbon is renowned for its impressive mechanical strength and stiffness. The integration of carbon fibers into the nylon matrix significantly enhances its structural integrity, allowing for the creation of parts that can withstand substantial stress and strain. This makes it an excellent material for applications in industries where durability and reliability are paramount, such as automotive, aerospace, and manufacturing. Kimya PA Carbon helps you achieve parts that are robust, with high dimensional stability and a nice matte finish!

Temperature and Chemical Resistance:

One of the standout features of Kimya PA Carbon is its excellent resistance to high temperatures (until 120°C) and chemicals. This property ensures that printed parts maintain their performance and dimensional stability even in elevated heat environments. Whether it’s under the hood of a car or in a high-temperature industrial setting, parts made from this filament can endure challenging conditions without compromising their integrity.

Ease of Printing and Dimensional Stability:

Despite its advanced properties, Kimya PA Carbon is surprisingly easy to print. It performs well on open chamber 3D printers, similar to other nylon filaments like Kimya PA6-CO. The carbon fibers not only contribute to the material’s strength but also play a crucial role in preventing warping during the printing process, ensuring a smooth and reliable print every time. Additionally, the filament leaves a nice matte finish to the printed parts, enhancing their aesthetic appeal.

Moisture Sensitivity and Preparation:

Like all polyamides, Kimya PA Carbon is sensitive to moisture. To achieve the best results, it is essential to dry the filament before printing at 80°C for 24 hours (mandatory). Proper preparation ensures that the material maintains its optimal properties, leading to higher quality and more consistent prints.

In summary, Kimya PA Carbon is a top-tier choice for those seeking a robust, reliable, and easy-to-use material for high-strength applications. Its superior mechanical properties, resistance to heat and chemicals, and excellent printability make it a standout filament in the 3D printing arena

recommended printing settings:

- Extrusion temperature: 270-290°C

- Bed temperature: 70-90°C

- Chamber temperature: 20-60°C (not mandatory)

- Printing speed: 40 – 70mm/s

| Spool Size | 500g, 1kg, 2kg |

|---|

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer