MakerBot Composite Extruder for Method MakerBot

$ 499,00 $ 149,70

The Composite Extruder for Method allows users to implement 3D printing with Nylon Carbon Fiber to create ultra-strong, metal replacement parts. The Composite Extruder for Method is ideal for applications that require loads over time, working prototypes for stress-testing, as well as end-use parts for a huge variety of professional projects.

3D PRINT STRONG, METAL-REPLACEMENT PARTS UTILIZING THE COMPOSITE EXTRUDER FOR MAKERBOT METHOD

The Composite Extruder for Method opens up new, advanced materials for users that want to 3D print with carbon-fiber infused nylon which is optimized for high strength, stiffness, and heat resistance.

-

Excellent strength to weight ratio – 110 MPa TS – for lightweight applications such as robotics end effectors

-

Engineering-grade stiffness – 7600 MPa Tensile Modulus – for structural applications such as vehicular brackets and inspection gauges

-

High heat resistance under load – 184°C HDT – for optimal under-hood and tooling applications

PRINTER COMPATIBILITY

-

Method

-

Method X

MATERIAL COMPATIBILITY

-

Nylon Carbon Fiber

-

ABS*

-

ASA*

-

PLA

-

Tough

-

PET-G

-

Nylon

-

PC-ABS and PC-ABS Fire Retardant*

*Only compatible with MakerBot Method X 3D printer

Manufacturer Product Code: 900-0064A

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Parts

3D Printer Parts

CNC Parts

CNC Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

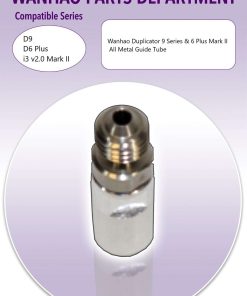

All Metal Guide Tube – Wanhao D9/D6Plus Mk2/i3Plus Mk2 Wanhao Precision Casting Co., Limited

3D Printer Parts

3D Printer Parts

3D Printer Parts