nano3Dprint – B3300 – 3D Multimaterials Printer Carbon Design Innovations, Inc.

$ 6.000,00 $ 1.500,00

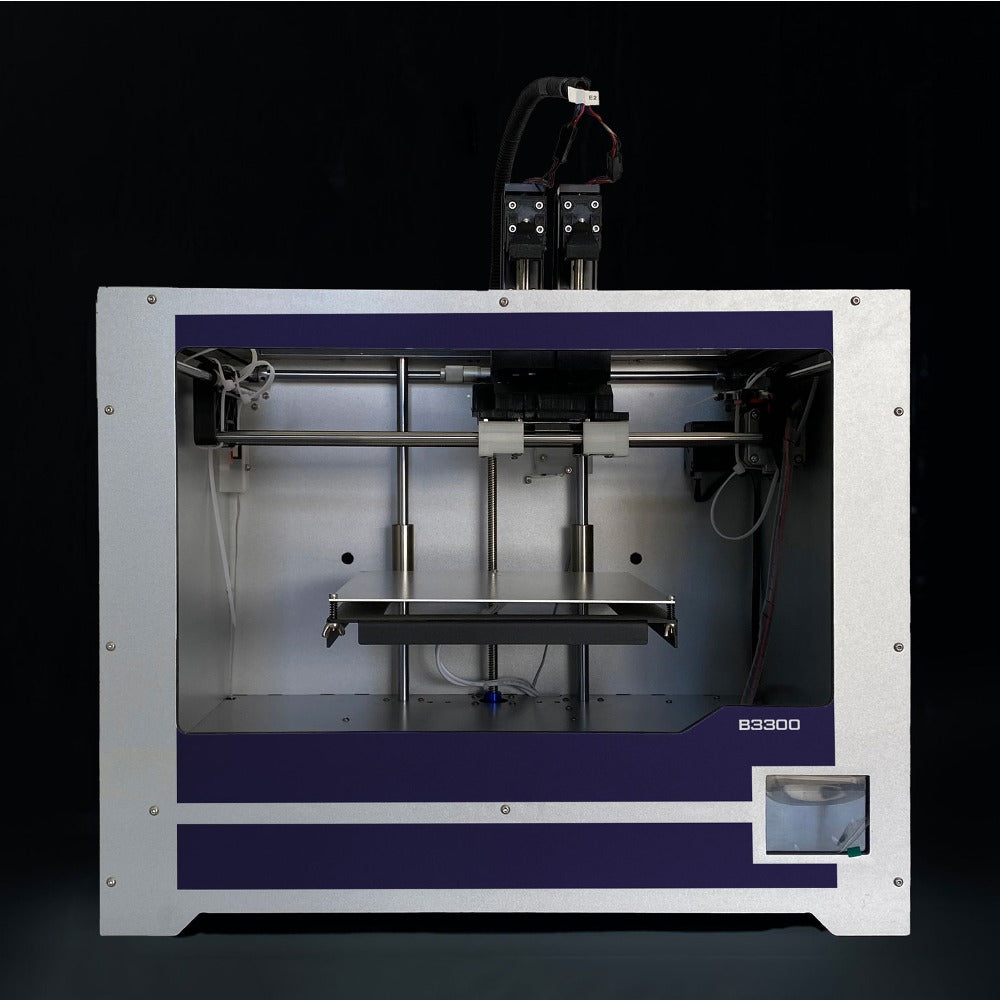

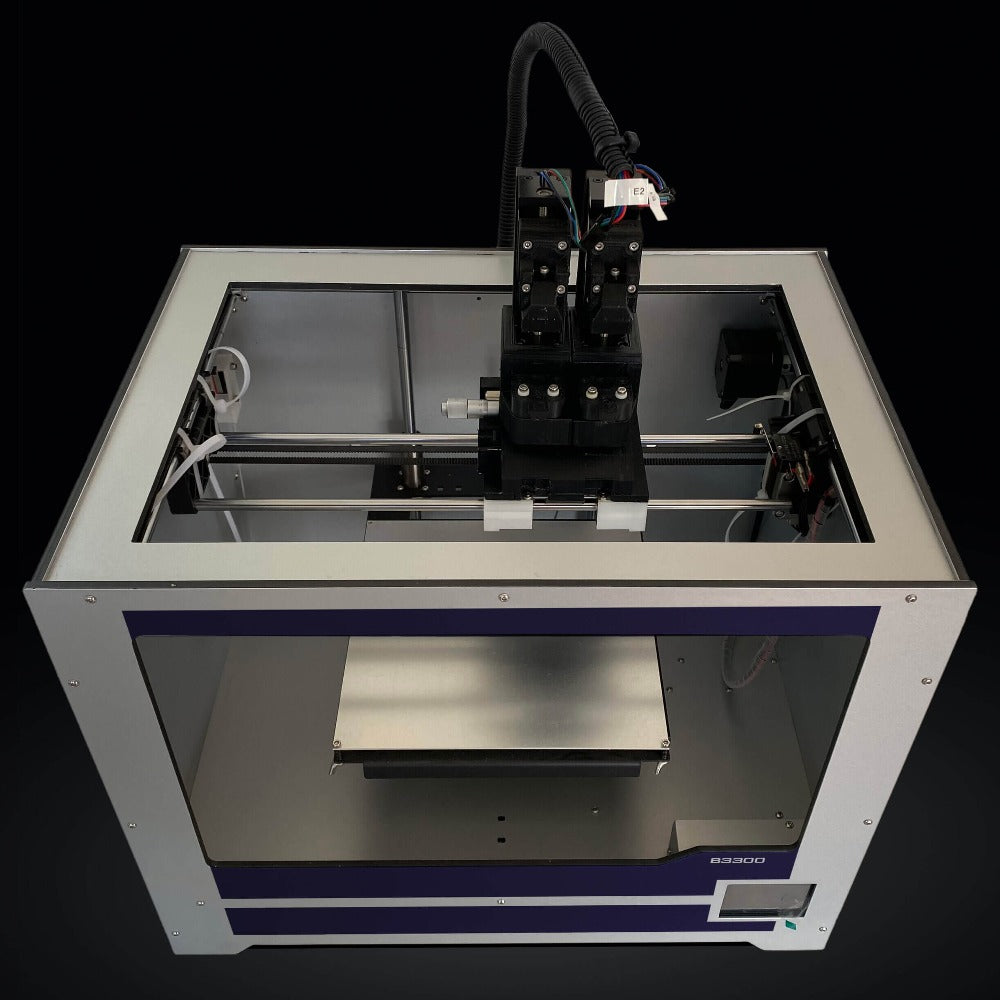

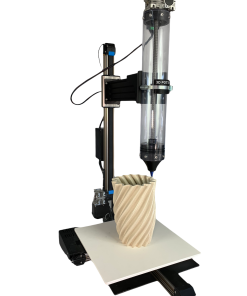

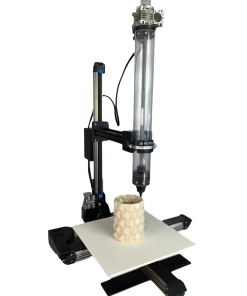

Nano3DPrint B3300

Multi-material Electronics 3D Printer

3D print functional inks and pastes side-by-side. Achieve new additive manufacturing with combined materials and high-resolution prints. Make wearables, sensors, and other electronics.

Make sensors, antennas, medical devices and more.

Use gold, ceramics, and a wide range of new materials.

Enjoy a significantly lower cost of ownership than similar 3D electronics printers.

Make the strongest 3D prints available with composite materials.

Make the strongest 3D prints available with composite materials.

Make the strongest 3D prints available with composite materials.

Side-by-side Dual Materials Dispensing System

Experience the future, the B3300 Dual Dispensing 3D Printer allows you to 3D print electronics with embedded circuitry right from your desk. Its dual proprietary materials dispensing systems can handle functional inks and pastes side-by-side, enabling you to use a range of materials such as conductive inks, medical-grade silicone, polyurethane rubber, plastics, rigid and flexible urethane foams, epoxies, and UV-curable polymers. This versatile printer is perfect for prototyping, manufacturing, customization, education and more.

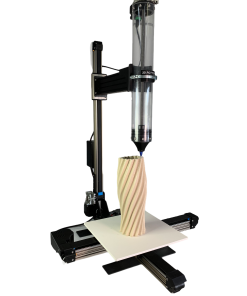

Print on Anything

Easily combine materials such as medical-grade silicone and gold or dielectrics with semiconductors. Create flexible wearables with embedded sensors and wires, using its ability to print medical-grade silicone housing alongside wires made from conductive inks or paste. It also has the capability to embed electronics into 3D prints, including sensors, strain gauges, heaters, complex antenna geometries, and optical components. Additionally, the B3300 can print onto pre-existing substrates and create new ones.

Don’t Add Wires, 3D Print Them

Nano3DPrint’s direct-write systems print a wide range of multi-materials side-by-side, so you can 3D print electronics housings as well as the internal circuitry. Embedding the connections between components allows for more conformal and complex features.

Machine Specs

Machine Dimensions

467 x 357 x 374 mm

Build Volume

214 x 186 x 160 (mm) 8.4 x 7.3 x 6.3 (in)

Positional Accuracy

XY axis: 0.11 mm Z axis: 0.0025 mm

Max Heat Bed Temperature

100°C

Max Nozzle Flow Rate

15 cc/hour

Max. Axis Moving Speed

125 mm/s

Two Printheads

Side-by-side Dual Materials Dispensing System

Video Inspection System

Real-time magnifying video inspection system for more precise adjustment control of the dispensing system.

The Materials Dispensing System 3D Prints:

Functional Pastes and Inks, Conductive Paints, Fast Drying Solvent Based Inks, Silver Nano-Particle Inks, Graphene solutions, and much more..

Software / File Format / Operating System

Compatible with Repetier-Host, Cura, Makerware, Simplify3D etc. / STL, GCODE, OBJ, DAE, AMF, BMP, JPG, JPEG, PNG / Windows, Mac, Linux

Connectivity

Direct print with SD card using full-color touch screen (recommended); Flash Drive

Rapid Prototyping

Time and cost-saving solutions for businesses and beyond. Get your inventions to the market with speed and efficiency. 3D printing reduces turnaround time from concept to finished product.

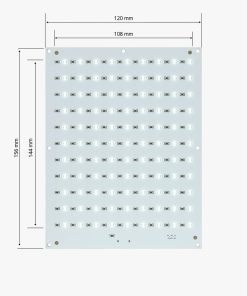

2D Printing

Use nano3Dprint for 2D printing applications. The high-precision, ultra reliable positive displacement print head is capable of precisely metering functional inks with viscosities ranging from 1mPa·s to 54000 mPa·s. Print with gold ink on PCB. Print interconnects with silver paste. Make a Linespace Array on Glass and print Coil on Kapton. The possibilities are endless.

Dual Material Dispensing Systems

The B3300 features dual dispeners. nano3Dprint’s proprietary dispensing systems handle functional inks and pastes side-by-side. Use materials such as conductive inks (Au, Ag, Cu, etc.), medical-grade silicone, polyurethane rubber & plastics, rigid & flexible urethane foams, epoxies, as well as UV-curable polymers.

Specs

| Two Printheads | Side-by-side Dual Materials Dispensing System |

|---|---|

| The Materials Dispensing System 3D Prints: | Functional Pastes and Inks, Conductive Paints, Fast Drying Solvent Based Inks, Silver Nano-Particle Inks, Graphene solutions, and much more… |

|

*For printing thermoplastics & inks/pastes side-by-side explore the capabilities of the A2200 |

|

| Syringe Size | 3 ml |

| Nozzle Size | 14 to 30 Ga (1.6 mm to 150 μm) Higher Resolution Available: 32 Ga, 34 Ga |

| Build Volume | 214 x 186 x 160 (mm) 8.4 x 7.3 x 6.3 (in) |

| Video Inspection System | Real-time magnifying video inspection system for more precise adjustment control of the dispensing system. |

| Machine Dimensions | 467 x 357 x 374 mm |

| Machine Weight | 13 kg (28.66 lbs.) |

| Max. Heat Bed Temperature | 100°C |

| Max. Axis Moving Speed | 125 mm/s |

| Max. Nozzle Flow Rate | 15 cc/hour |

| Positional Accuracy | XY axis: 0.11 mm Z axis: 0.0025 mm |

| Printing Layer Height | ≥ 0.02 mm |

| Stage Material | Removable Glass Heated Bed |

| Software / File Format / Operating System | Compatible with Repetier-Host, Cura, Makerware, Simplify3D etc. / STL, GCODE, OBJ, DAE, AMF, BMP, JPG, JPEG, PNG / Windows, Mac, Linux |

| Connectivity | Direct print with SD card using full-color touch screen (recommended); Flash Drive |

Included

| 1 B3300 3D Multi-material Electronics Printer | Camera and Holder |

|---|---|

| Screws (for dispenser installation) | Allen Wrenches |

| Scraper (x1) | Tweezer (x1) |

| Glue Stick (x1) | Empty Syringes (x10) |

| Syringe and Nozzle Caps (x10 each) | Transfer Adapters (x10) |

| Bed Clips (1 set) | Glass Bed (x1) |

| Power Cable (x1) |

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer Parts

Bambu Lab Heatbed Surface Magnet (with Cutout) – P1 Series Bambu Lab

3D Printer Parts

3D Printer Parts

All Metal Guide Tube – Wanhao D9/D6Plus Mk2/i3Plus Mk2 Wanhao Precision Casting Co., Limited

3D Printer Parts

3D Printer Parts

3D Printer Parts