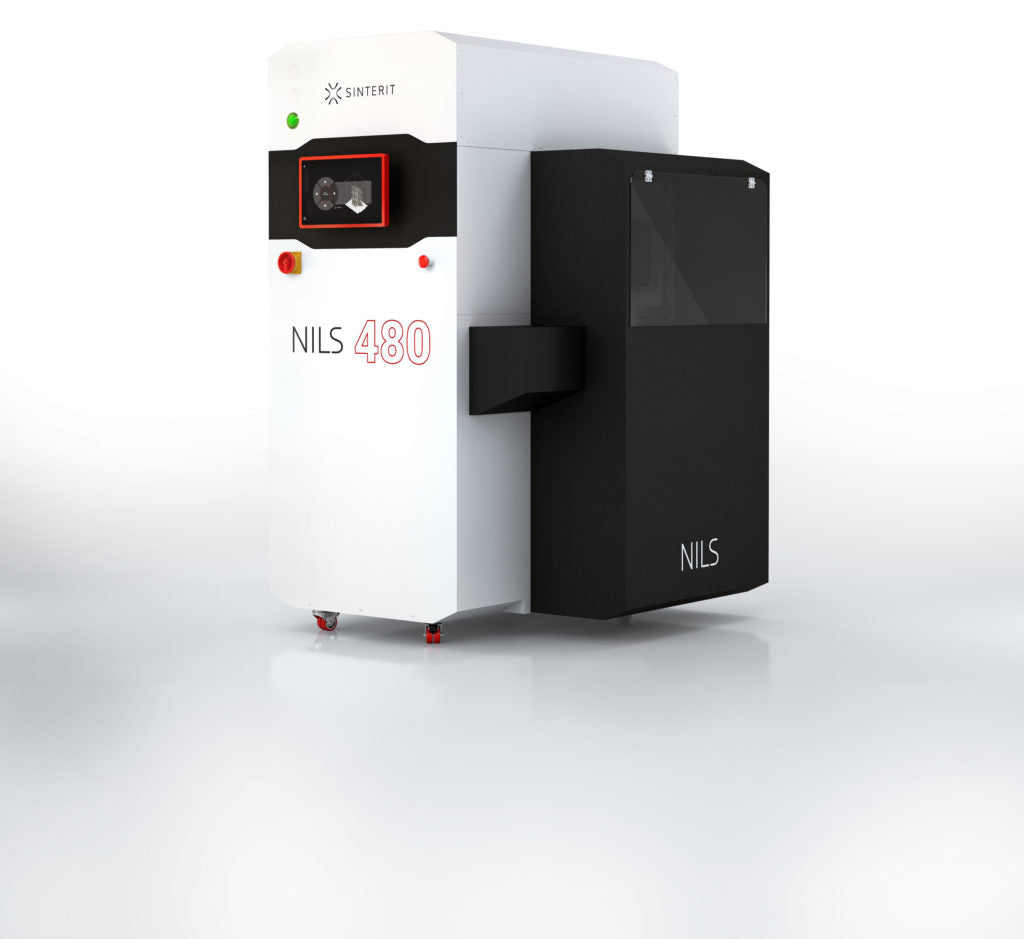

Sinterit NILS 480 Sinterit

$ 69.990,00 $ 17.497,50

New Industrial Laser Sintering 3D Printer

At nearly 10 times the speed and 4 times the size, the NILS 480 is a production-ready, industrial SLS 3D printer at 1/4 the closest competitors’ price. With the reinvented productivity features in the NILS 480, you can print more, continuously.

Special order terms apply. Payment in full required when order is placed. This item cannot be returned or cancelled for any reason. All purchase orders require payment in full by ACH bank transfer.

Please Note: Requires freight shipment for delivery.

Key Features & Benefits

Industrial Printing Speed

The NILS 480 is equipped with the Galvo laser scanning system. This means most printing jobs can be finished within 24 hours.

Industrial Build Size

The NILS 480 meets the industrial market standard for size, enabling you to print much more at lower prices per part.

Innovative Automated Systems

With its Continuous Printing and Automatic Powder Dispensing Systems, you can do the same work much more efficiently. If you print a lot, these features really matter.

Best ROI on the SLS Market

With the speed, build size and automated work the NILS brings, you achieve superior ROI in an industrial SLS printer – in as little as 40 days.

NILS 480

Continuous Printing System

With this solution, fill the powder once and print two full beds or a few lower print beds. All of this without repeating the print preparation process and powder filling. How does the NILS do this? The previous bed automatically ejects, lifting a full cake to the cooling box. The printing bed comes back and another print automatically begins.

Easy Operation

With automated systems, an effective ecosystem with post-processing, and easy material change, you can be sure the printing experience will be smooth and simple.

Automatic Powder Dispensing System

Just fill the container with powder and let the printer manage the rest of the process. This is possible thanks to the special closed powder circuit, which circulates the powder and automates the powder dispensing. No manual work with powder is required until you receive the final print cake.

32 Open Printing Parameters

Each of our materials has an optimized profile that allows you to gain the best quality and personalization. When you’re ready to modify or make your own profile for changing printout properties, the NILS’ 32 parameters can be adjusted.

Technical Specifications

General

| Laser Type | IR 30W |

| Laser Scanner Type | Galvo |

| Machine Dimensions | 1285 x 1250 x 1840 mm (50.6 x 49.2 x 72.4 in) |

| Weight | 300 kg / 660 lbs |

Printer Parameters

| Max Size of Print (Diagonally) | 435 mm / 17.1 in |

| Max Print Volume | 200 x 200 x 330 mm / 7.9 x 7.9 x 13.0 in |

| Layer Height Z (Min – Max) | 0.075 – 0.175 mm / 0.003 – 0.006 in |

| Build Speed | Up to 14 mm/h / up to 0.56 in/h |

| Inert Gas Control System | Built-In |

Software

| Supported File Types | STL, 3MF, OBJ, 3DS, FBX, DAE |

| OS Compatibility | Microsoft Windows 10 or Higher |

Materials

Standard Prototyping Materials

PA12 Smooth

A cost effective nylon 12 powder with excellent surface resolution. Perfect for detailed objects and general prototypes.

Learn More

PA11 Onyx

Bio-based polyamide powder material (nylon) with good mechanical properties combined with good flexibility and impact strength.

Learn More

Performance & Special Applications

PA11 CF (Carbon Fiber)

One of the strongest and most versatile materials available on the SLS printing powder market.

Learn More

PA11 ESD

Specialized PA11 material with heat resistance and ESD functionality.

Learn More

Polypropylene (PP)

Discover new applications with a polymer that was not accessible with Compact SLS solutions until now.

Learn More

Flexible Materials

FLEXA Grey

TPU material enabling high-elasticity prints.

Learn More

FLEXA Bright

A functional rubber material that can be dyed.

Learn More

FLEXA Soft

Soft material that can be used in design, art and to simulate really soft materials.

Learn More

TPE

Use TPE to print functional prototypes such as pumps, bellows, gaskets, and other elastic solutions for working in difficult conditions.

Learn More

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer

3D Printer