UltiMaker Factor 4 3D Printer Ultimaker North America

$ 19.500,00 $ 4.875,00

UltiMaker Factor 4

Industrial-grade performance. Reliable, repeatable results

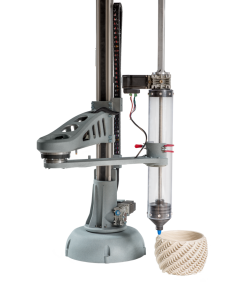

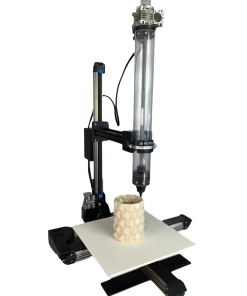

An end-to-end application solution, UltiMaker Factor 4 is tailored for the development, production, and full-confidence deployment of process-critical tools and machine components. Factor 4 keeps operations running, simplifying processes in factories, and reducing human-triggered variabilities. It streamlines factory floor operations with its large effective build volume, direct dual material extrusion, and onboard print process reporting to achieve unrivaled predictability and minimal variance.

The application solution for manufacturing operations

Target Applications

- Small batches of auxiliary components.

- Manufacturing aids including jigs, fixtures, and assembly tools.

- Durable spare, bridge, and service parts for real working conditions.

- Functional engineering prototypes.

New Hardware Features

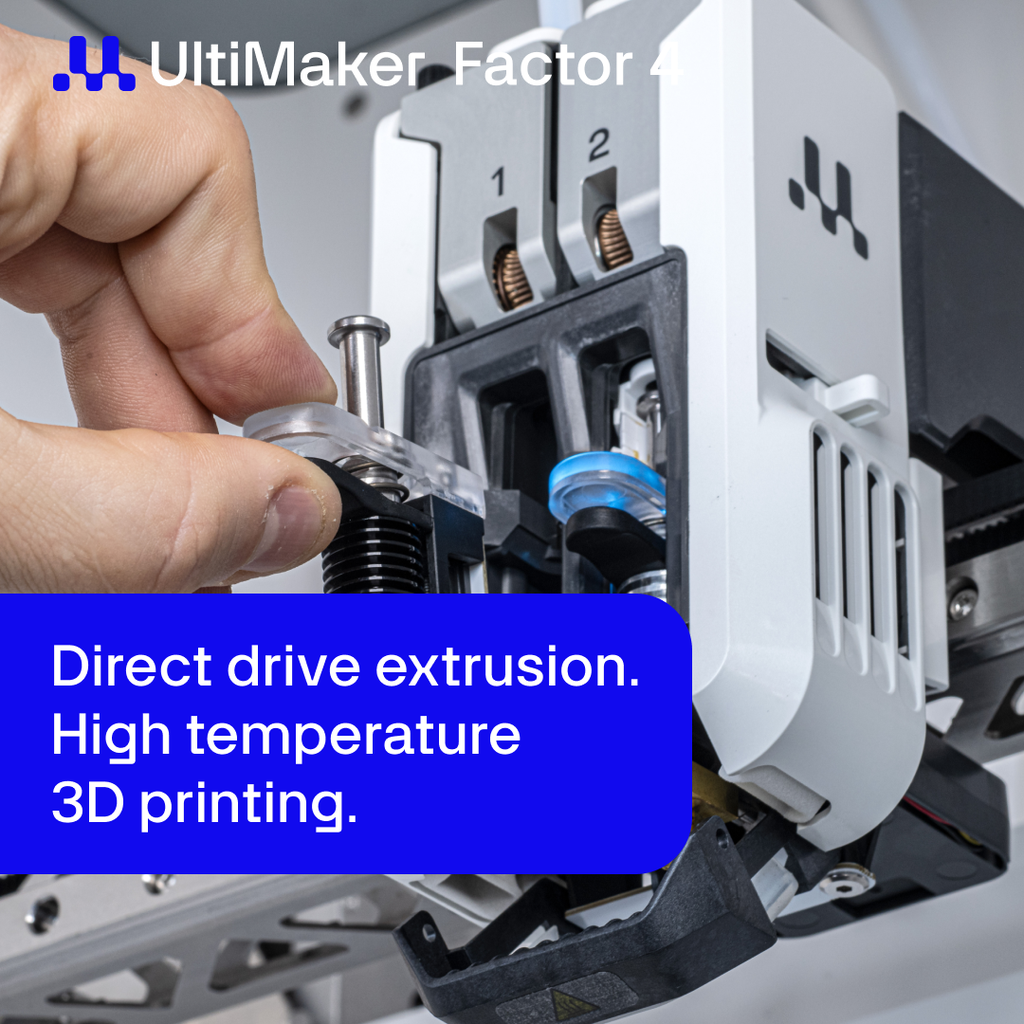

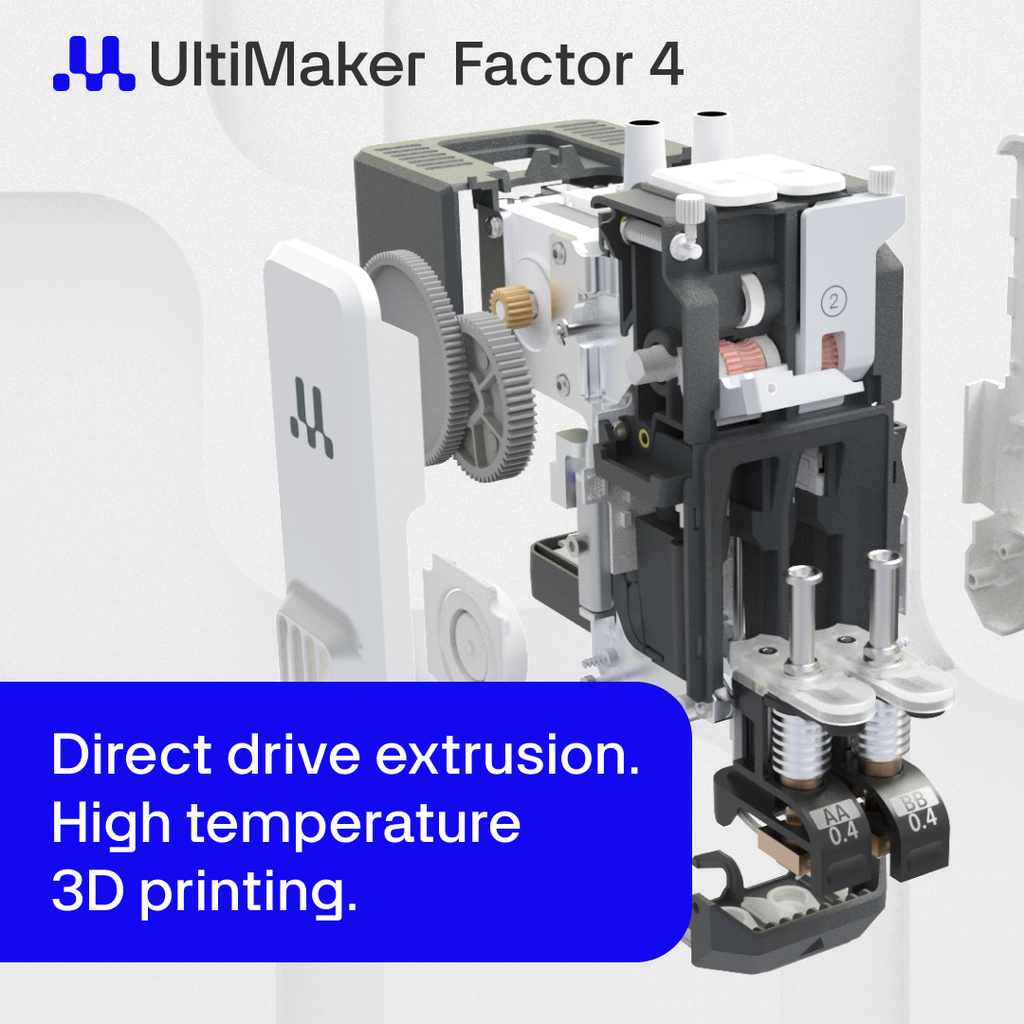

- Dual extrusion direct drive print head

- Actively controlled build volume temperature

- Effective build volume of 330 X 240 mm in XY

- Automated material handling system with low relative humidity storage

Materials

- 14+ Ultimaker materials with NFC recognition

- Widest choice of 200+ profiled materials on Ultimaker Marketplce

- Including flexible, low Shore A thermoplastic elastomers

- Plus composites, mid-high temperature polymers, and stainless steel

Software

- Powered by the Ultimaker Cura

- Ultimaker Digital Factory for secure printer management file storage, and analytics

- Onboard print process reporting for part validation and structural integrity verification

- Integration with industry-leading software solutions

Service

- Highly modular design for fast and easy repairs

- Achieve high uptime with Ultimaker Extended service Policies through Ultimaker customer support agents and our network of service providers

Access to 200+ Marketplace Materials

A wide range of high-performance and certified material properties opens up a huge range of new 3D printing applications on Factor 4.

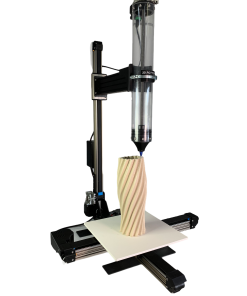

Manufacturing tools that streamline production

When you need to keep operations running,Factor 4 can help simplify factory processesand reduce human-related inconsistencies. Itfacilitates operations with direct dual material extrusion, support for engineering materials,and onboard print process reporting to achieve unrivaled predictability and minimal variance

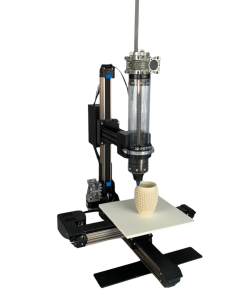

High-fidelity functional engineering prototypes

The ability to accurately reproduce functional parts in a wide variety of engineering materials accelerates testing and innovation. Factor 4 is a low-emission, low-maintenance platform that’s safe to leave unattended. Stay in full control with over 400 Cura settings and in-depth part validation tools

Innovation powered by material diversity

UltiMaker PPS-CF is a new high-temperature composite for Factor 4 that can replace complex steel parts. Its heat deflection temperature is greater than 230°C. It’s chemical resistant and flame retardant (UL94 V0), making it a versatile choice for demanding application.

Tested for Accuracy

We have verified dimensional accuracy within ±0.2mm or ±0.2% nominal length over the full printer build volume using PPS CF, PET CF, Tough PLA, and PET.

Edge-to-edge Dual Extrusion

3D print with confidence across every millimeter of the 330 x 240mm flexible build plate. And quickly remove parts thanks to its PEI coatin.

Packed with Technology for Maximum Predictability

The combination of the all-new H-bridge gantry and direct drive extrusion print head allows high-speed movement and positional accuracy of ±0.2 mm or ±0.2% of the feature’s nominal length with UltiMaker Verified Materials. This results in best-in-class dual material printing speeds so that you can quickly create the flexible or strong parts you need.

Hassle-free Material Handling

A new, integrated, automatic material handling system reliably manages your spools so you don’t have to. The internal chamber is kept at less than 10% RH in office conditions, so you can keep up to 6 kilograms of filament in perfect condition for back-to-back print jobs.

Innovation powered by material diversity

- UltiMaker Factor 4 raises the temperature up to 340°C using the HT print core.

- This means that you can now 3D print higher temperature-resistant and durable materials with more confidence.

- The temperature within the fully enclosed build volume is also controlled up to 70°C, with a heated bed up to 120°C, ensuring optimal material-specific processing conditions and consistent part quality wherever the 3D printer is located.

Seamless Software Integration

UltiMaker Cura and Digital Factory work together with Factor 4 and UltiMaker materials to provide an easy, secure, and reliable workflow – from 3D model to printed part.

UltiMaker Cura: Easy print preparation for manufacturing

Our software leads the AM industry with its powerful slicing engine. A variety of file types including native CAD files can be directly imported and quickly sliced with pre-tuned application intent profiles. Cura also features:

- Over 400 settings to make granular adjustments

- Material interlocking for unrestricted multi-material combinations

- Sequential printing, ideal for small-batch production

- Regular updates that constantly improve the printing experience

UltiMaker Digital Factory: Secure, efficient 3D printing management

With shared workspaces, assigned roles, and file management using the digital library, coordinating your printing schedule is simple. The live HD camera feed on every Factor 4 combined with progress and status updates makes it trivial to handle multiple prints on multiple printers with zero downtime. Digital Factory also includes:

- In-depth analytics for review and forecasting (with CSV export)

- An overview and history of printer maintenance tasks

- Secure remote control to reprint jobs without reslicing

Onboard structural integrity validation

After every print job, receive an in-depth report on extrusion parameters deviations from nominal values, their locations, and their severity in the 3D model. Using a suite of sensors in the print head, build chamber, and material loading system, this print process reporting helps to verify and validate part quality before use in the field.

Modularity at your service

UltiMaker Factor 4 was designed to be modular. This means less production downtime in the event that a part of the printer needs servicing. Under the UltiMaker Factor 4 service plans, an expert technician anywhere in the world will be able to quickly swap the faulty part out for another so you can get up and running again as quickly as possible.

Application and material-matching print cores

UltiMaker print cores feature a quick-swap design and EEPROM chip. They are recognized by Cura and can be quickly changed without tools to meet the requirements of any print job, increasing your efficiency and decreasing downtime.

| Type | Nozzle Sizes | Max.Temp | Materials |

| AA | 0.25, 0.4, 0.8 | 280°C | Up to Polyamides 6, TPU,PC, ABS, PETG |

| BB | 0.4, 0.8 | 280°C | PVA and other water soluble materials |

| CC | 0.4, 0.6 | 300°C | Composites, metal |

| DD | 0.4 | 340°C | High-temp composites, PPS CF, PEKK-A |

A safe and function printer station to support Ultimaker Factor 4

Increased ease of use

- Easy and safe access to printer rear side for main tenance and repair

- Safe displacement and transport

- Minimal floor occupancy

Built-in Safety

- Tailor-made for Factor 4

- Anti-tilting architecture and stability tailored for Factor 4

- Lock in mechanisms to fix printer to cabinet

Ergonomically Designed

- Perform operations at right height and comfort

- Store 18 spools and accessories with lockable drawers

| Printing Properties | Technology | Fused deposition modeling (FDM) |

| Extrusion system | Dual-extrusion, direct drive print head with unique auto-nozzle lifting system and swappable print cores | |

| Build Volume | Single material printing: 330x240x300mm (13×9.4×11.8in). Dual material printing: 330x240x300mm (13×9.4×11.8in) | |

| Filament Diameter | 2.85mm | |

| Print Profiles Availability | 14+ UltiMaker materials. 200+ UltiMaker Marketplace materials | |

| Dimensional Accuracy | ±0.2mm ±0.2% feature nominal length. For detailed conditions visit ultimaker/factor4 | |

| Hardware Properties | XYZ Resolution | 6.25,7.8,2.5micron |

| Homing sensor | Optical | |

| Build Plate | PEI-coated flexible build plate | |

| Build Plate Temperature | Up to 120°C | |

| Build Volume Temperature | Actively controlled up to 70°Cwith nozzle plane temperature uniformity within: ±3°C for temperatures <50°C ±5°C for temperatures <70°C | |

| Extrusion flow | Closed loop flow compensation | |

| Max. Extrusion Temperature | 280°C: Print core AA, BB, DD. 300°C: Print core CC. 340°C: Print core HT. | |

| Compatible Print Cores | Print core AA (0.25mm, 0.4mm, 0.8mm). Print core BB (0.4mm, 0.8mm) Print core CC (0.4mm, 0.6mm). Print core DD (0.4mm) – available in selected regions. Print core HT (0.6mm) | |

| Closed Loop Fans | Air filtering fan, air recirculation fans, print cooling fans, print core cooling fan | |

| Material handling capacity | 6 bays with NFC recognition (max. 1kg spool size) | |

| Material humidity control | Average relative humidity <15% in all operational conditions | |

| Filtration system | HEPA H13 | |

| Monitoring | HDR (high dynamic range) 1920×1080 px HD camera | |

| Emission rate (UFP & VOC) | UltiMaker filaments below limits listed in UL-2904 | |

| Display | 7-inch touchscreen (resolution 1024x600px) | |

| Connectivity | Wi-Fi 2.4&5GHz: IEEE 802.11a/b/g/n/ac LAN: Gigabit Ethernet USB: 2.0 | |

| System on module | NXP i.MX8 Mini Quad (4×1.8GHz), ARM Cortex-A53, 2GB LPDDR4 16GB eMMC | |

| Real time controller | i.MX RT1064, Arm Cortex-M7 600MHz, 1MB SRAM | |

| Power requirement | 100–240V AC, 50–60Hz max., 6A | |

| Physical Dimensions | Dimensions | 695x605x1287mm (27.5x24x51in) |

| Weight | 120kg (265lbs) | |

| Shipping dimensions | 760x800x1587mm (30×31.5×62.5 in) | |

| Shipping weight | 137kg (309lbs) | |

| Ambient Conditions | Operating sound | <50 dBA in operation |

| Operating environment | Operating: Temperature: 18°C–30ºC, humidity: 30–70% RH. Storage: Temperature: 5°C–40ºC, humidity: 20–90% RH | |

| Software | Print job preparation | UltiMaker Cura 5.7.1 or newer |

| Print job management | UltiMaker Digital Factory | |

| File types supported | UltiMaker Cura: STL, OBJ, 3MF. Printable formats: G, GCODE, UFP, STEP | |

| System requirement | Windows 7 (64-bit), Mac OS X 10.12, OpenGL 2.1 4GB RAM (8GB recommended) | |

| Print process reporting | Supported | |

| Security | Active firewall and PIN code settings protection | |

| Safety and compliance | Warranty period | 12 months limited warranty |

| Certifications | For a detailed list of certifications visit ultimaker/factor4 | |

| Safety features | Red stop button immediately stops motion and heat sources. Open door sensor pauses motion and extrusion |

The Widest Material Choice on the Market

Choosing the right material is critical to the success of your 3D print. UltiMaker’s open filament system lets you print with any 2.85 mm filament, and print profiles from the UltiMaker Marketplace streamline print preparation and maximize your print success rate.

UltiMaker PETG

Multi-Color | Easy | Tough | Chemical resistant | Temperature Resistant | Wear Resistant

UltiMaker PLA

Easy | High Stiffness | High Strength | Multi-Color | Visual | Translucent

UltiMaker Tough PLA

Easy | High Stiffness | High Strength | Tough | Impact Resistant

UltiMaker ABS

Tough | High Strength | Multi-Color | Impact Resistant

UltiMaker Nylon

Tough | Wear Resistant | Translucent | Low Friction

UltiMaker PVA

Support Material | Water-Soluble

UltiMaker Breakaway

Support Material | Easy

UltiMaker CPE

High Strength | Mutli-Color | Translucent

UltiMaker CPE+

High Strength | Heat Resistant | Temperature Resistant | Translucent

UltiMaker TPU 95A

Flexible | Tough | Wear Resistant

UltiMaker PP

Flexible | Wear Resistant | Translucent

UltiMaker PC

High Stiffness | High Strength | Tough | Flame Retardant | Translucent | Temperature Resistant | Impact Resistant

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

All Metal Guide Tube – Wanhao D9/D6Plus Mk2/i3Plus Mk2 Wanhao Precision Casting Co., Limited

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts