UltiMaker S5 Ultimaker North America

$ 6.950,00 $ 1.737,50

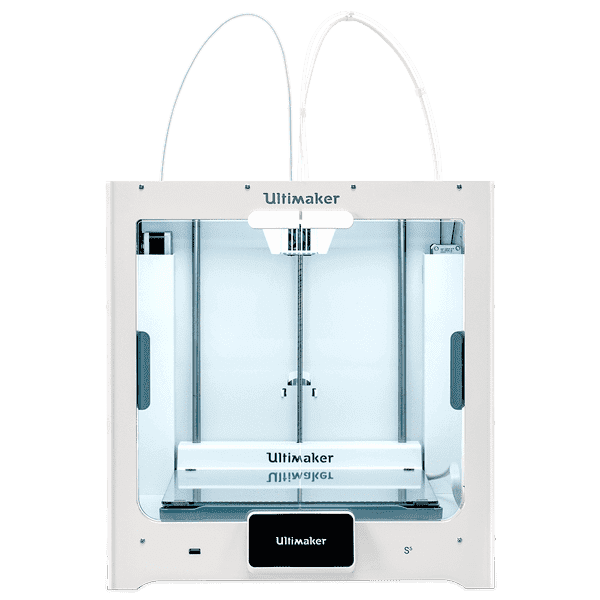

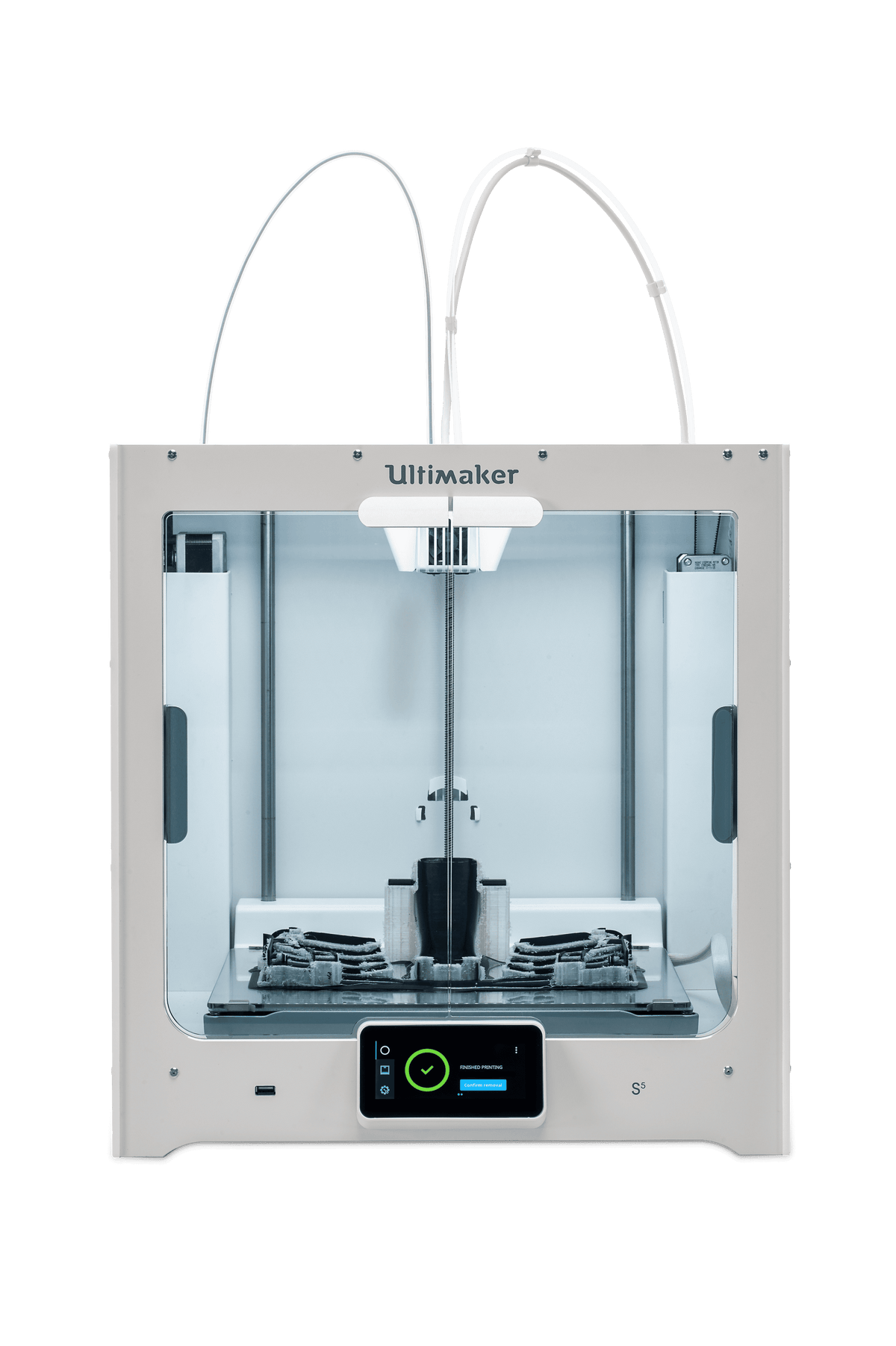

Ultimaker S5 3D Printer

Expand your 3D Printing Ambitions

Ultimaker’s flagship 3D printer offers reliable dual extrusion on a larger scale. Create functional prototypes, production tools, and strong end-use parts made from advanced polymers and composite materials – thanks to tested, predefined print settings. The Ultimaker S5 also features advanced active leveling, filament flow sensors, and an intuitive touchscreen to make your 3D printing experience simpler and easier.

Key Features & Benefits

24/7 capacity. Always-on productivity

Composite-ready dual extrusion

330 x 240 x 300 mm build volume

Advanced auto bed leveling

Compatible with over 200 materials

Enhanced Reliability

With the Ultimaker S5’s enhanced reliability, you can trust it to do its job right the first time, while you get back to work. With advanced active bed levelling, the S5 always lays down a perfect first layer. The Ultimaker S5’s dual filament flow sensors will pause your print and notify you if you run out of material. These features, combined with Ultimaker’s class leading build quality, give you a printer that is sturdy, reliable, and reduces time spent trying to find problems.

Larger Build Volume

The Ultimaker S5 boasts a large build volume of 330 x 240 x 300 mm (13 x 9.4 x 11.8″). Meet your demand with increased efficiency by printing larger parts or multiple smaller parts at once. The Ultimaker S5 gives you all this space to work while fitting comfortably on your desk or workstation.

Advanced Filament Compatibility

Ultimaker works tirelessly to work with the leading material manufacturers around the globe to provide Ultimaker users with pre-tuned settings for the best filament to meet your use-case. The Ultimaker S5 is an easy way to print with some of the world’s most advanced filaments – including glass and carbon fiber composites.

Free Access to Ultimaker Essentials

Ultimaker Essentials gives you the tools you need to start 3D printing at work, while meeting IT requirements. Features include remote printer management, firmware firewalls, verified plugins, and direct support.

3 Easy Steps to Transform your Workflow

1. Prepare Your Model

Import from CAD, choose your material, slice with optimized settings, and remotely send your print job – all in a few clicks.

2. Start 3D Printing

Get on with your work, knowing the Ultimaker S5 is reliable and safe for unattended use.

3. Use Your Part

Create prototypes, tools, and parts with almost any mechanical properties – thanks to world-leading material compatibility.

Complete the Bundle

Upgrade to 24/7 Productivity

Combining the Ultimaker S5 with the Air Manager, and Material Handling Station gives you full environmental control of the entire 3D printing process from start to end. Up to 6 rolls of filament can be stored and automatically managed in the Material Handling Station, controlling humidity to provide super reliable printing. Using the air manager also allows you to passively heat the build chamber and filter up to 95% of ultrafine particles, creating a safer working environment.

Trusted by the World’s Leading Brands

What UltiMaker’s Partners Say

Volkswagen

“Last year, we produced around 1,000 different 3D printed parts. The benefits of these are improved ergonomics, productivity, and operator satisfaction. In the end, we get very good feedback from the operators working on the line.”

Luis Pascoa, Pilot Plant Manager at Volkswagen Autoeuropa

Read the full story

Heineken

“So far in the pilots that have ran, we’ve significantly seen a cost reduction in the functional applications that we’ve found from 70 – 90%. On delivery time we’ve seen the same decrease.”

Isabelle Haenen, Global Supply Chain Procurement at Heineken

Read the full story

ZEISS

“We chose UltiMaker because the machines are reliable and the results are repeatable. That’s important for us, for a stable production process.”

Johannes Grimm, Manager Operation Excellence at Carl Zeiss Optical Components

Read the full story

Ford

“If you compare our 3D printed tools to conventionally manufactured tools, we can easily save approximately €1,000 per tool, which is of course a lot when you consider all the tools which are needed to produce a vehicle.”

Raphael Koch, Research Engineer R&A at Ford Europe

Read the full story

Compare UltiMaker’s 3D Printers

|

|

|

|

|

|

|---|---|---|---|---|---|

| Ultimaker S7 Pro Bundle | Ultimaker S7 | Ultimaker S5 | Ultimaker S3 | Ultimaker 2+ Connect | |

| Dedicated Support | ✓ | ✓ | ✓ | ✓ | ✓ |

| Geared Feeder | ✓ | ✓ | ✓ | ✓ | ✓ |

| Heated Build Plate | ✓ | ✓ | ✓ | ✓ | ✓ |

| Touchscreen | ✓ | ✓ | ✓ | ✓ | ✓ |

| Network Connectivity | ✓ | ✓ | ✓ | ✓ | ✓ |

| Dual Extrusion | ✓ | ✓ | ✓ | ✓ | |

| Swappable Print Cores | ✓ | ✓ | ✓ | ✓ | |

| Filament Flow Sensor | ✓ | ✓ | ✓ | ✓ | |

| Composite and Metal Compatibility | ✓ | ✓ | ✓ | ✓ | |

| Largest Build Volume | ✓ | ✓ | ✓ | ||

| PEI Flex Plate | ✓ | ✓ | |||

| Inductive Senor Active Bed Leveling | ✓ | ✓ | |||

| Automatic Bed Tilt Compensation | ✓ | ✓ | |||

| Print Head Anti-flood Sensor | ✓ | ✓ | |||

| Environment Control | ✓ | ✓ | |||

| Automatic Material Handling | ✓ | ||||

| Filament Humidity Control | ✓ | ||||

Technical Specifications

Dimensions

- Build Volume: 330 x 240 x 300 mm (13 x 9.4 x 11.8″)

- Assembled Dimensions: 495 x 585 x 780 mm (19.5 x 23 x 30.7 inches)

- Printing Technology: Fused Filament Fabrication (FFF)

- Compatible Filament Diameter: 2.85 mm

- Weight: 20.6 kg (45.4 lbs)

- Power Input: 100-240 VAC, 50-60 Hz

- Maximum Power Output: 500W

Printer Properties

-

Layer Resolution:

- 0.25 mm nozzle: 150 – 60 micron

- 0.4 mm nozzle: 200 – 20 micron

- 0.6 mm nozzle: 300 – 20 micron

- 0.8 mm nozzle: 600 – 20 micron

- XYZ Resolution: 6.9, 6.9, 2.5 micron

- Feeder Type: Dual-geared feeder, reinforced for composite materials

- Display: 4.7-inch (11.9 cm) color touchscreen

- Print Core Replacement: Swappable print cores

- Print Head: Dual extrusion print head with an auto-nozzle lifting system and swappable print cores

- Nozzle Diameters: 0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm

Operation Parameters

- Build Speed: < 24 mm³/s

- Nozzle Temperature: 180 – 280°C

- Nozzle Heat-Up Time: < 2 minutes

- Operating Sound: < 50 dBA

- Build Plate Leveling: Advanced Active Leveling

- Build Plate: 20 – 140°C heated glass build plate

- Build Plate Heat-Up Time: < 4 minutes (from 20 to 60°C)

- Operating Ambient Temperature: 15 – 30 °C (59 – 86 °F), up to 70% relative humidity

- Non-Operating Temperature: 0 – 32 °C (32 – 90 °F)

Ecosystem

-

Supplied Free Software:

- Ultimaker Cura – Print Preparation Software

- Ultimaker Digital Factory – Printer Management Software

- Supported OS: MacOS, Windows, Linux

- Plugin Integration: SolidWorks, Siemens NX, Autodesk Inventor

-

Supported File Types:

- Ultimaker Cura: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG

- Printable formats: G, GCODE, GCODE.gz, UFP

- File Transfer: Wi-Fi, Ethernet, USB

Service & Support

-

Training:

- Training is available online or via our dedicated network of local service partners.

- Register your Ultimaker S5 for a free, online setup and onboarding tutorial in the Ultimaker 3D Printing Academy.

- Included Warranty Period: 12 months (Upgradable with purchase of extended service plan)

- Expert Support: Market-leading technical support via email, phone, or from our global community is available to you in your language and time zone.

- Extended Support: Online resources, extensive manuals, material technical and safety data sheets (in multiple languages), a detailed knowledge base, and much more.

Compliance

- Certification: CE, FCC, VPAT, RoHS, REACH, CB, BIS, KC, PSE, RCM, SRRC, MIC, NCC, Safe unattended professional use

- Information: Learn about Ultimaker S5 safety and compliance

Transform Your Business

With the Ultimaker 3D Printing Platform

The Ultimaker S5 3D Printer gives you access to the entire Ultimaker ecosystem, including:

- Ultimaker Essentials (unending enterprise software subscription)

- Ultimaker Cura (full settings and monitoring compatibility)

- Ultimaker Digital Factory (remote printing and management)

- Ultimaker 3D Printing Academy (e-learning modules)

- A global network of service partners (setup and training)

The Widest Material Choice on the Market

Choosing the right material is critical to the success of your 3D print. UltiMaker’s open filament system lets you print with any 2.85 mm filament, and print profiles from the UltiMaker Marketplace streamline print preparation and maximize your print success rate.

UltiMaker PETG

Multi-Color | Easy | Tough | Chemical resistant | Temperature Resistant | Wear Resistant

UltiMaker PLA

Easy | High Stiffness | High Strength | Multi-Color | Visual | Translucent

UltiMaker Tough PLA

Easy | High Stiffness | High Strength | Tough | Impact Resistant

UltiMaker ABS

Tough | High Strength | Multi-Color | Impact Resistant

UltiMaker Nylon

Tough | Wear Resistant | Translucent | Low Friction

UltiMaker PVA

Support Material | Water-Soluble

UltiMaker Breakaway

Support Material | Easy

UltiMaker CPE

High Strength | Mutli-Color | Translucent

UltiMaker CPE+

High Strength | Heat Resistant | Temperature Resistant | Translucent

UltiMaker TPU 95A

Flexible | Tough | Wear Resistant

UltiMaker PP

Flexible | Wear Resistant | Translucent

UltiMaker PC

High Stiffness | High Strength | Tough | Flame Retardant | Translucent | Temperature Resistant | Impact Resistant

Ultimaker Product Number: 218252

Professional packing and fast shipping

Due to our longstanding partnership with UPS FedEx DHL and other major global carriers, we are able provide a range of shipping options. Our warehouse staff is highly trained to package your goods exactly as per the specifications we offer. Before shipping the goods are carefully inspected and secured. Everyday we deliver thousands of packages to customers from all over the world. This is a testament to our commitment to be the largest online retailer worldwide. The warehouses and centers for distribution are situated in Europe and the USA.

Orders with more than one item are given processing time for each item.

Before shipping, we will conduct a thorough inspection of the items you've ordered. Currently, most orders are shipped within 48-hours. Expected delivery time is between 3 and 7 days.

Returns

The stock is dynamic and we do not fully manage it because of the fact that multiple stakeholders are involved, including our factory and warehouse. The actual levels of stock can change at any moment. It's possible that the stock may run out after your order has been placed.

The policy is 30 days. If you haven't received the product within 30 days, we are not able to issue a refund or an exchange.

For your item to be returned, it must be unopened and in the same state as you received it in. It must also be in the original packaging.

Related products

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer Parts

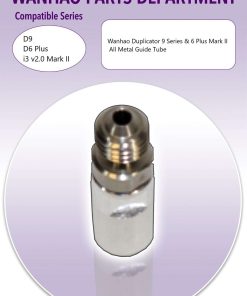

All Metal Guide Tube – Wanhao D9/D6Plus Mk2/i3Plus Mk2 Wanhao Precision Casting Co., Limited

3D Printer Parts

3D Printer

3D Printer Parts

3D Printer

3D Printer Parts

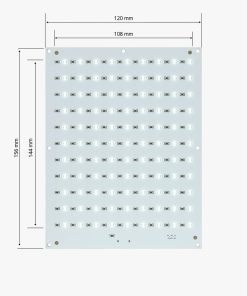

Bambu Lab Heatbed Surface Magnet (with Cutout) – P1 Series Bambu Lab

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts

3D Printer Parts